Pelletizing Systems & Feed Pellet Mill Models

Pelletizing Systems

Pelletizing Systems - Products

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Pelletizing Systems All Products

Industrial Pelletizing Systems and Pellet Press Machines

Sustainable profitability in the feed industry begins at the intersection of low energy consumption and high product quality. The feed technologies we offer as Atlas Yem do more than just process raw materials; they provide engineering solutions that elevate them to the highest bioavailability levels. In our feed production plant projects, our focus is on minimizing operating expenses (OPEX) while ensuring the physical and nutritional standards that increase the market value of the final product.

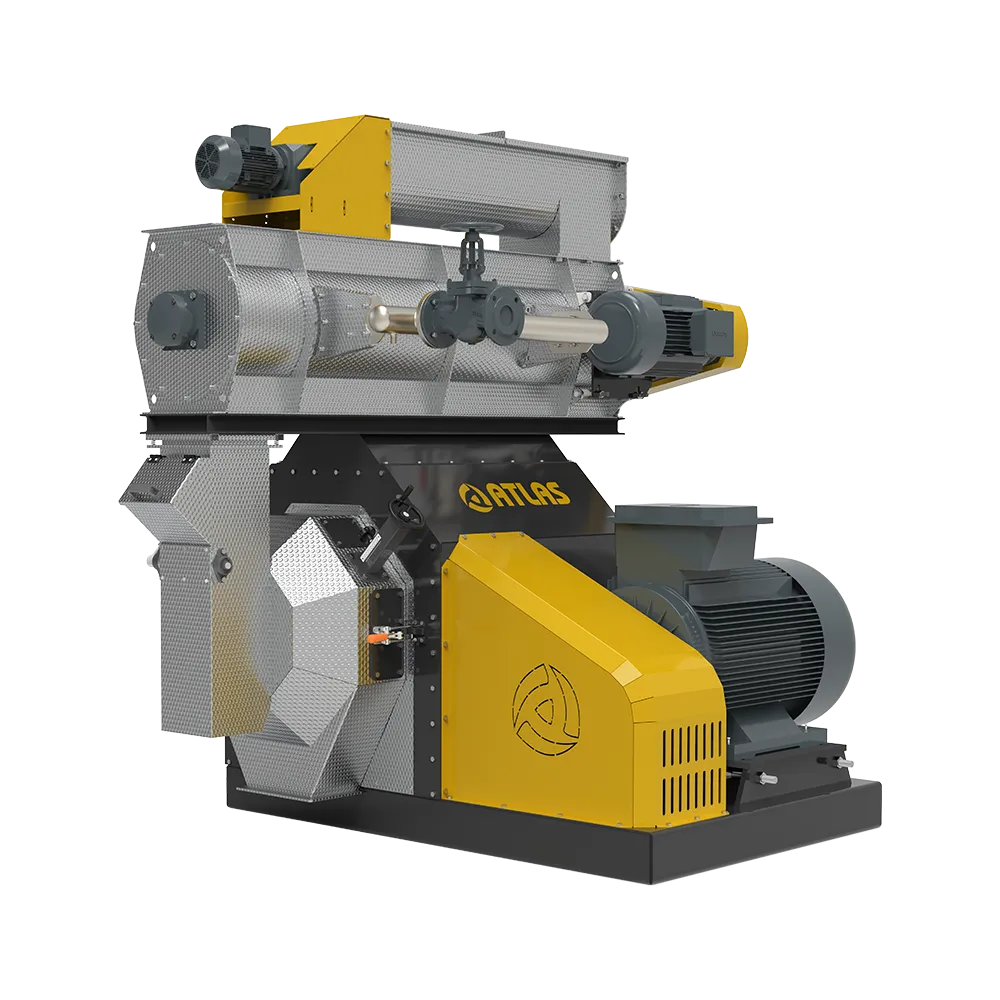

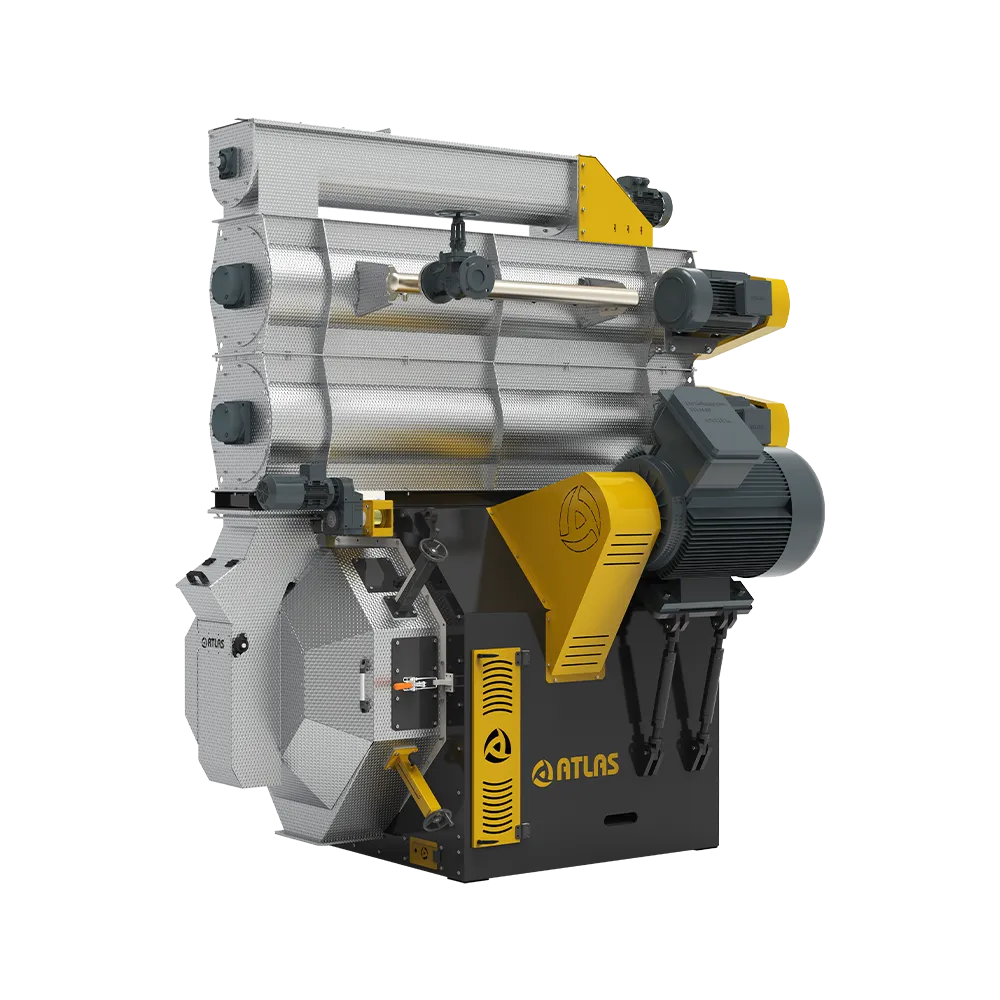

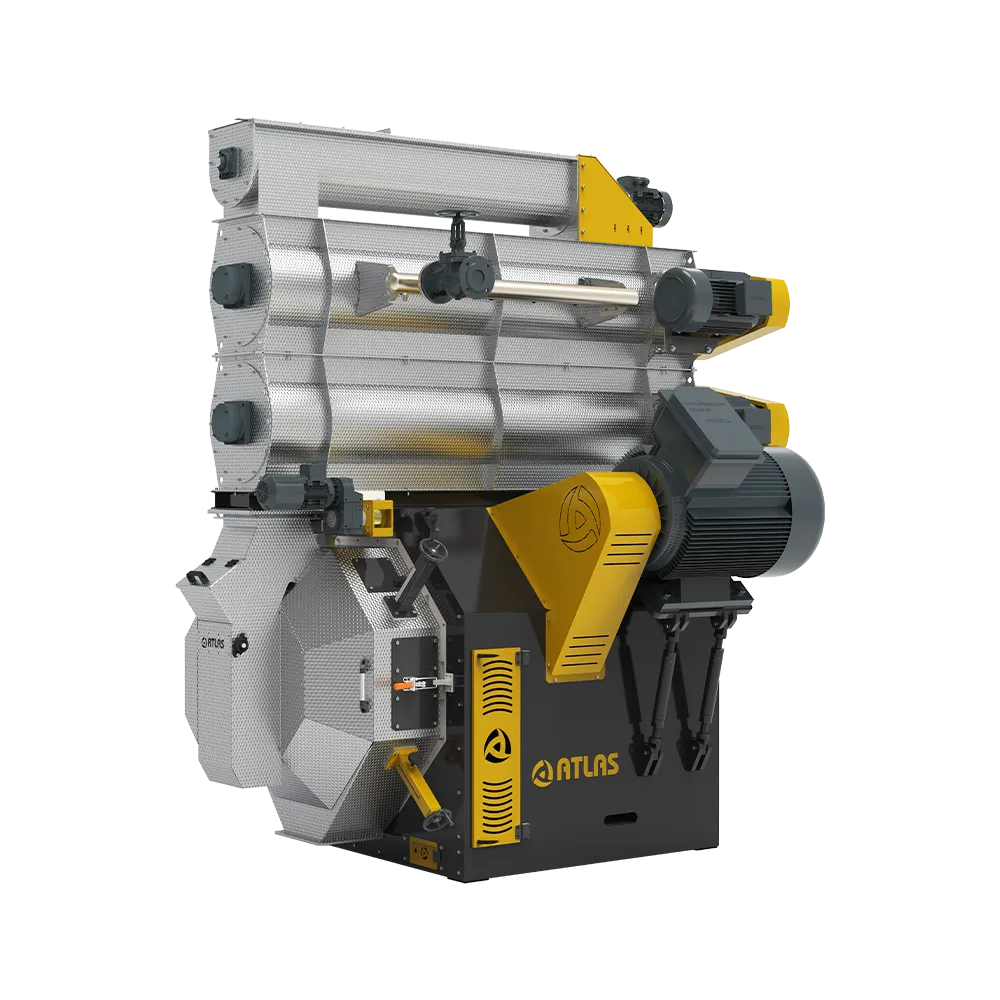

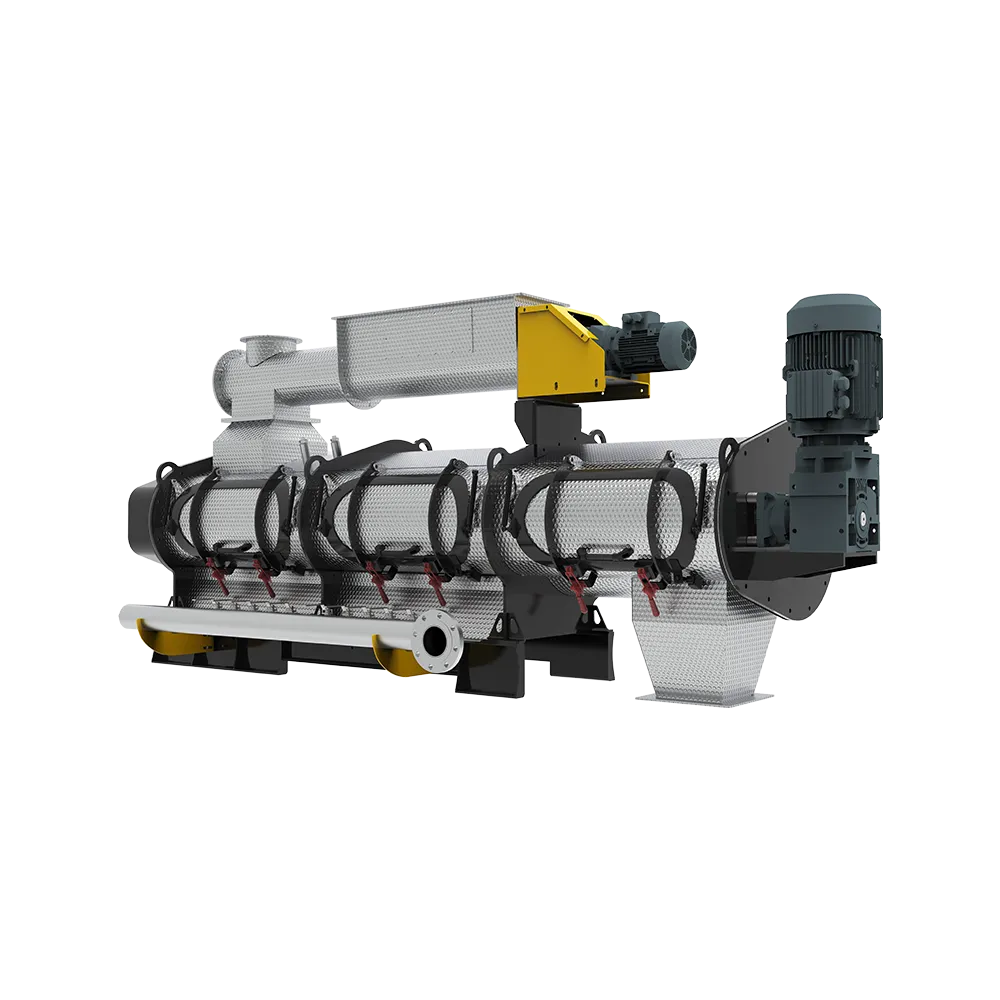

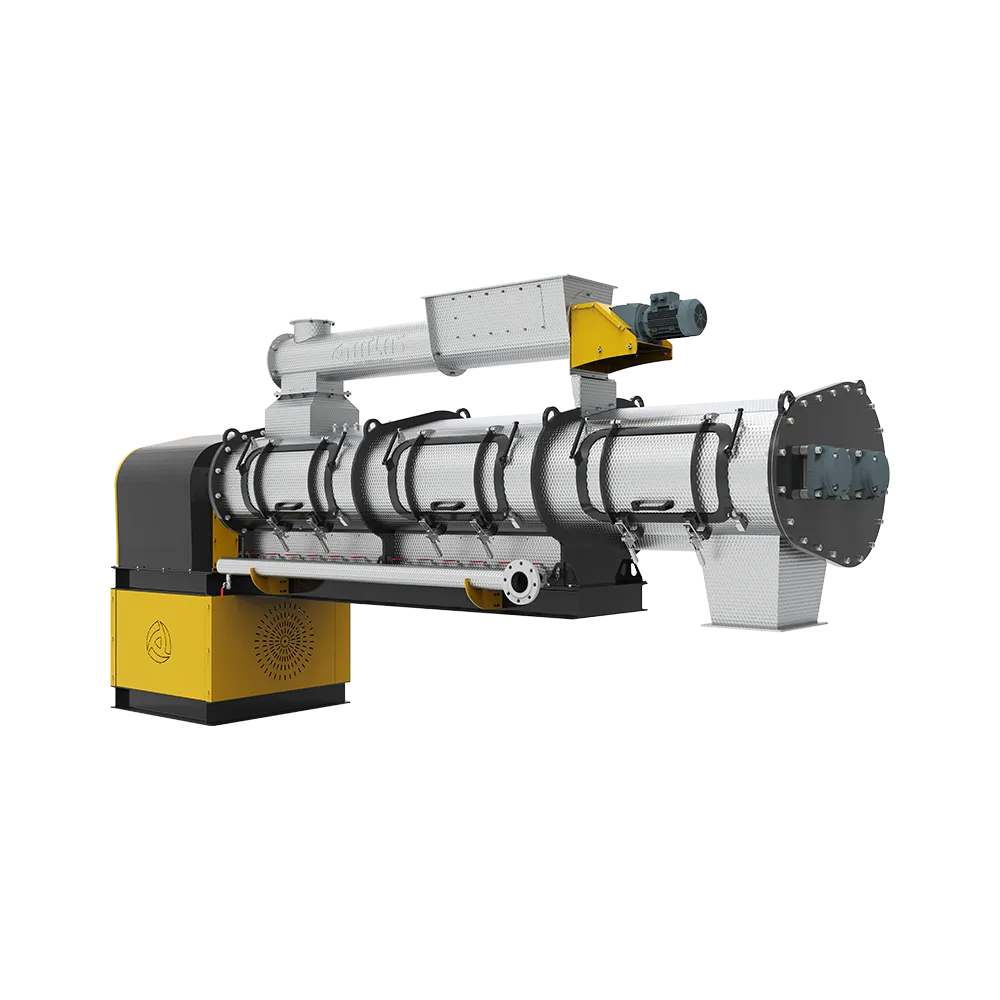

Pelletizing Systems: Maximum PDI and Low Fines Ratio

Pellet Durability Index (PDI) directly affects the loss rate in logistics processes and the feed intake rate of animals. Atlas Yem pelletizing systems optimize the thermal and mechanical processing of the mash feed, allowing you to produce dust-free pellets with high digestibility. Our systems, showing high performance in cattle feed, poultry feed, and pet food production lines, are designed for 24/7 uninterrupted operation.

Pellet Press and Operational Durability

Our standard pellet press models offer stability even in high-tonnage production with heavy-duty body structures and optimized roller-die clearances. Thanks to heat-treated components, wear costs are reduced, and mechanical resistance against sudden load changes is maximized. As a leading feed pellet machine provider, we ensure that our equipment withstands the most demanding industrial environments.

Geared Pellet Press: Maximum Energy Efficiency

For facilities aiming to reduce energy costs, the geared pellet press (gearbox driven) we developed provides up to 15% more power transmission efficiency compared to belt-driven systems. The direct drive pellet mill structure eliminates belt slippage and friction losses, transferring the total motor power directly to the pelleting chamber. This translates into a tangible reduction in electricity costs per ton and shortens the payback period of your machinery investment.

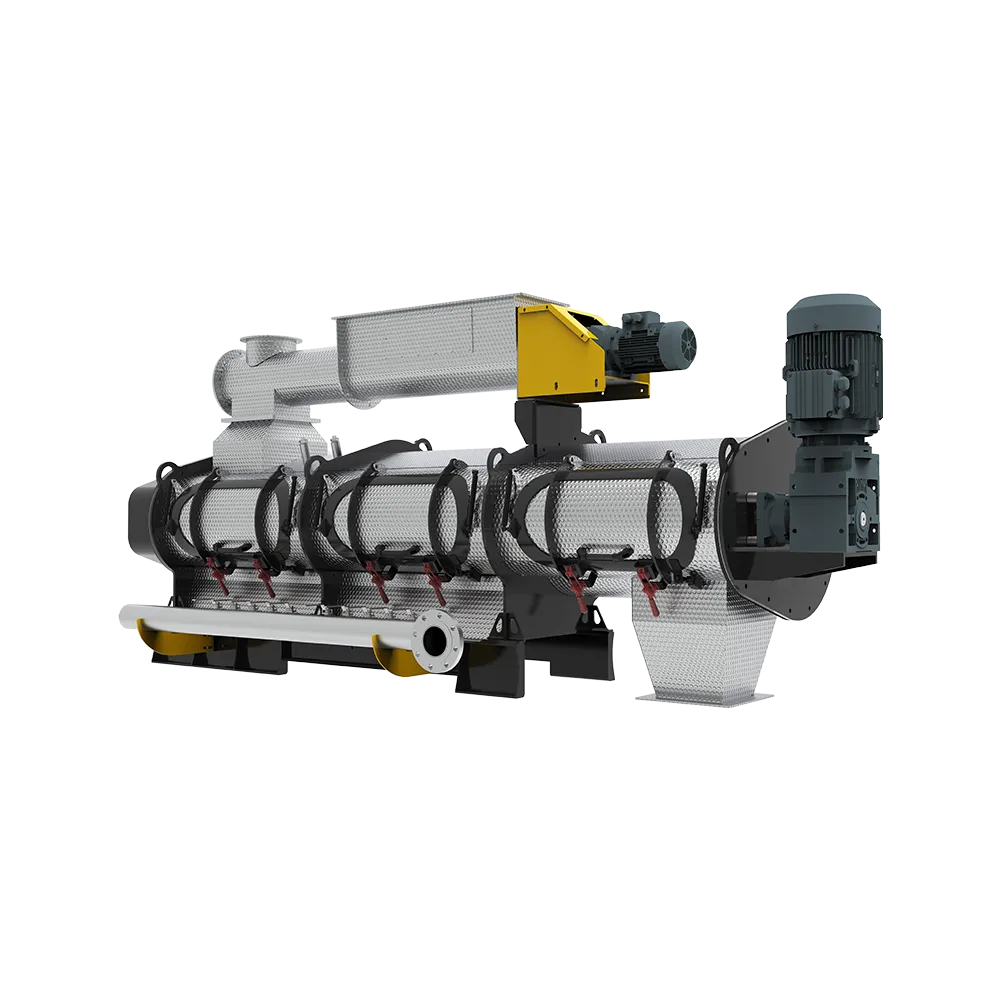

Feed Conditioner: Optimal Gelatinization and Hygiene

60% of pellet quality is determined during the conditioning stage. Atlas Yem conditioner units ensure that steam and heat penetrate the feed homogeneously, resulting in total starch gelatinization. Our steam conditioner systems eliminate pathogens to ensure the microbiological safety of the feed while extending the die life of the pellet mill.

Advanced Steam Conditioning and Retention Management

With its stainless steel internal structure and adjustable paddle angles, the retention time is managed precisely according to the type of ration. Whether it is a single shaft conditioner or a double shaft conditioner, Atlas Yem technology ensures the feed reaches the ideal temperature and moisture levels before entering the pellet press, guaranteeing superior durability and animal performance.

14 from the product 1–12 Showing between

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Pellet Press All Products

Atlas Yem pelletizing technology is engineered with high-torque drive mechanisms and optimized compression geometries. Our Pellet Press systems ensure maximum Pellet Durability Index (PDI) with minimal energy consumption.

Pellet Press: Industrial Authority in Feed Pelletizing Systems

In the global industrial feed sector, the Pellet Mill is the heart of production. The efficiency of a Pelletizing System determines the physical quality and nutritional availability of the feed. At Atlas Yem, we specialize in building the ultimate Feed Pelletizer solutions that focus on thermal treatment and high-pressure compaction. A professional Pellet Press does more than just shape the feed; it eliminates pathogens through heat and ensures that every pellet carries the exact nutritional value intended in the ration. By reducing fines and increasing density, our systems optimize storage and transport logistics for global feed producers.

Gear Driven Pellet Mill: The Pinnacle of Torque and Efficiency

For large-scale operations, the Gear Box Pellet Press is the industry standard for durability. Our Gear Driven Pellet Mill models offer superior power transmission compared to traditional belt-driven systems. This ensures that the Feed Pellet Machine operates at peak performance even under the heavy resistance of fiber-rich or high-oil formulations. By reducing power loss, we help producers lower their operational expenses (OPEX) per ton of feed produced. Every unit is reinforced with heat-treated alloy dies to withstand 24/7 heavy-duty industrial cycles.

Poultry Feed and Cattle Feed Pelletizing Excellence

Atlas Yem provides specialized solutions tailored to different animal species. Whether you are looking for a Poultry Feed Pellet Machine designed for rapid throughput and optimal starch gelatinization, or a Cattle Feed Pellet Mill capable of handling dense ruminant rations, our engineering is optimized for your specific needs.

-

Chicken Feed Pelletizer: Focused on hygiene and consistent particle size for starter and finisher feeds.

-

Aquatic and Pet Food: High-precision machines for floating or sinking fish feed and high-density pet food kibbles.

-

Conditioning Excellence: Every system is equipped with an advanced Feed Conditioner or Steam Conditioner to ensure the mash reaches the correct temperature for hygiene and durability.

Operational Stability and Long-Term Durability

The longevity of a Pelletizing System depends on the quality of its wear parts and the robustness of its main frame. Atlas Yem utilizes heavy-duty rollers and precision-drilled dies to ensure our machines withstand the mechanical stress of continuous production. Our commitment to engineering excellence means less downtime and more consistent production for your facility.

Technical Features of Atlas Pellet Press Systems

-

Advanced Steam Conditioning: Stainless steel Steam Conditioner for optimal starch gelatinization and pathogen control.

-

High PDI Guarantee: Engineering designs that ensure minimal fines and maximum pellet durability.

-

Automation Integration: Fully compatible with modern PLC systems for smart load management and roller adjustment.

-

Heavy-Duty Construction: Reinforced steel body designed for extreme mechanical stress and vibration-free operation.

-

Global Spare Part Support: Reliable supply of high-quality dies and rollers for long-term operational security.

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Geared Pellet Press All Products

Engineering Power: Geared Pelletizing Technology

In the global industrial feed sector, efficiency is defined by the seamless transfer of power to production. Geared Pellet Press systems offer significantly higher operational stability compared to traditional belt-driven models. Atlas Yem’s advanced geared pellet mill technology ensures maximum torque transmission through a heavy-duty gearbox, minimizing energy loss and reducing the operational expense (OPEX) per ton of feed.

Maximum Torque and Superior Pellet Durability (PDI)

Pelletizing is the process of compacting mash feed under high pressure and steam. The constant RPM and high torque provided by the geared system ensure a superior Pellet Durability Index (PDI). Whether in poultry feed pelleting or heavy cattle feed pelleting, our geared systems maintain peak performance across all industrial rations without any drop in rotation speed.

Industrial Advantages and ROI

-

Energy Efficiency: Zero power loss from belt slippage ensures lower electricity costs.

-

Heavy-Duty Construction: Engineered for 24/7 continuous feed pelletizing in massive plants.

-

Extended Component Life: Geared drives reduce mechanical fatigue, significantly extending the lifespan of the pellet mill dies and rollers.

For more information, Please contact us.

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Conditioner All Products

The Architect of Pellet Quality: Conditioning Technology

In a feed production line, conditioning is the most strategic stage where raw materials undergo physical changes via steam and heat before entering the pellet press. Atlas Yem conditioner systems precisely manage the moisture and temperature balance of the mash feed, maximizing pelleting efficiency. A proper steam conditioning process not only improves the Pellet Durability Index (PDI) but also significantly reduces energy consumption.

Starch Gelatinization and Nutritional Optimization

The feed conditioner units engineered by Atlas Yem facilitate the gelatinization of starch within the raw material. This process enhances the digestibility of the feed, directly contributing to animal performance. Furthermore, the high-temperature hygienization process eliminates pathogens in the feed, ensuring the highest standards of biological safety.

Technical Advantages and Variations

-

Material Durability: Full stainless steel (AISI 304/316) construction resistant to wear and corrosion.

-

Precision Steam Injection: Multi-point steam inlets for uniform conditioning across the product.

-

Adjustable Paddles: Angled paddles to optimize the retention time of the feed.

-

Model Diversity: Single, double, and long-term retention conditioner configurations for various industrial needs.