Industrial Mixing Systems & Feed Mixers | Atlas Yem

Mixing Systems

Mixing Systems - Products

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Mixing Systems All Products

Mixing Systems: The Art of Homogeneity in Feed Production

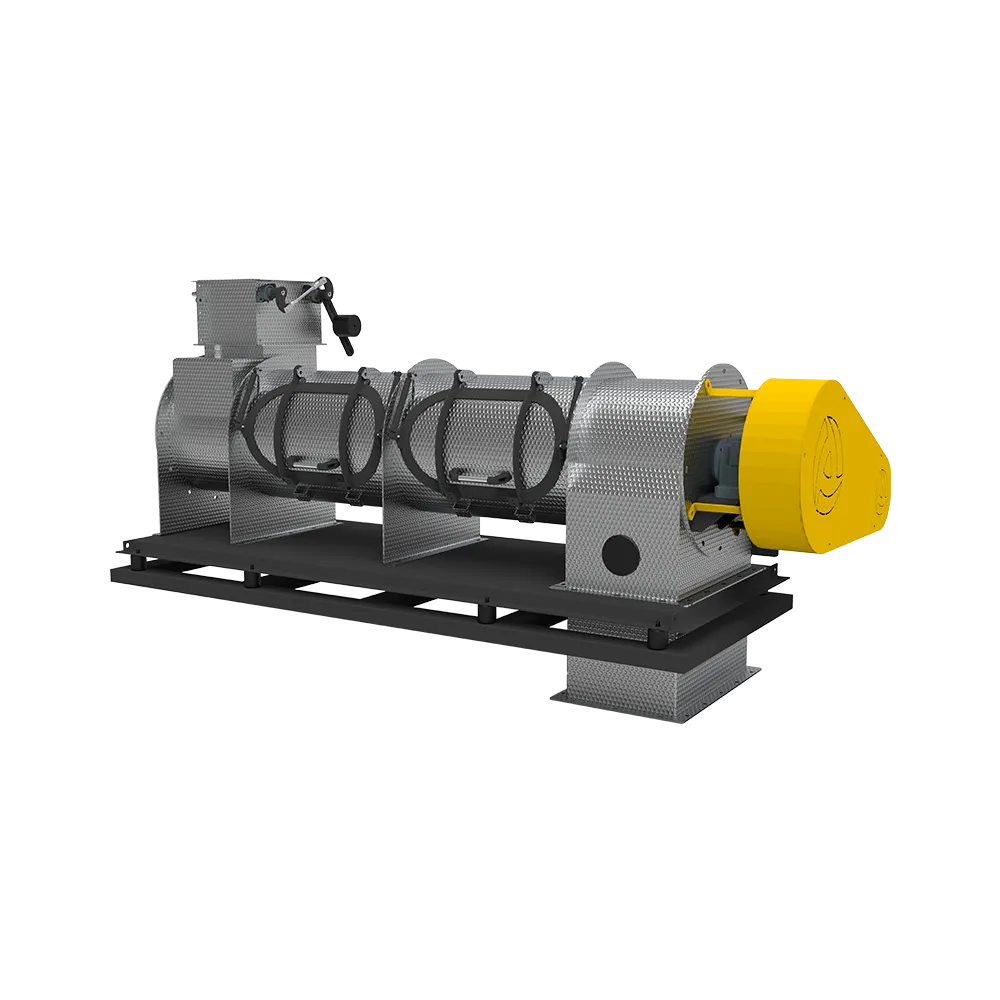

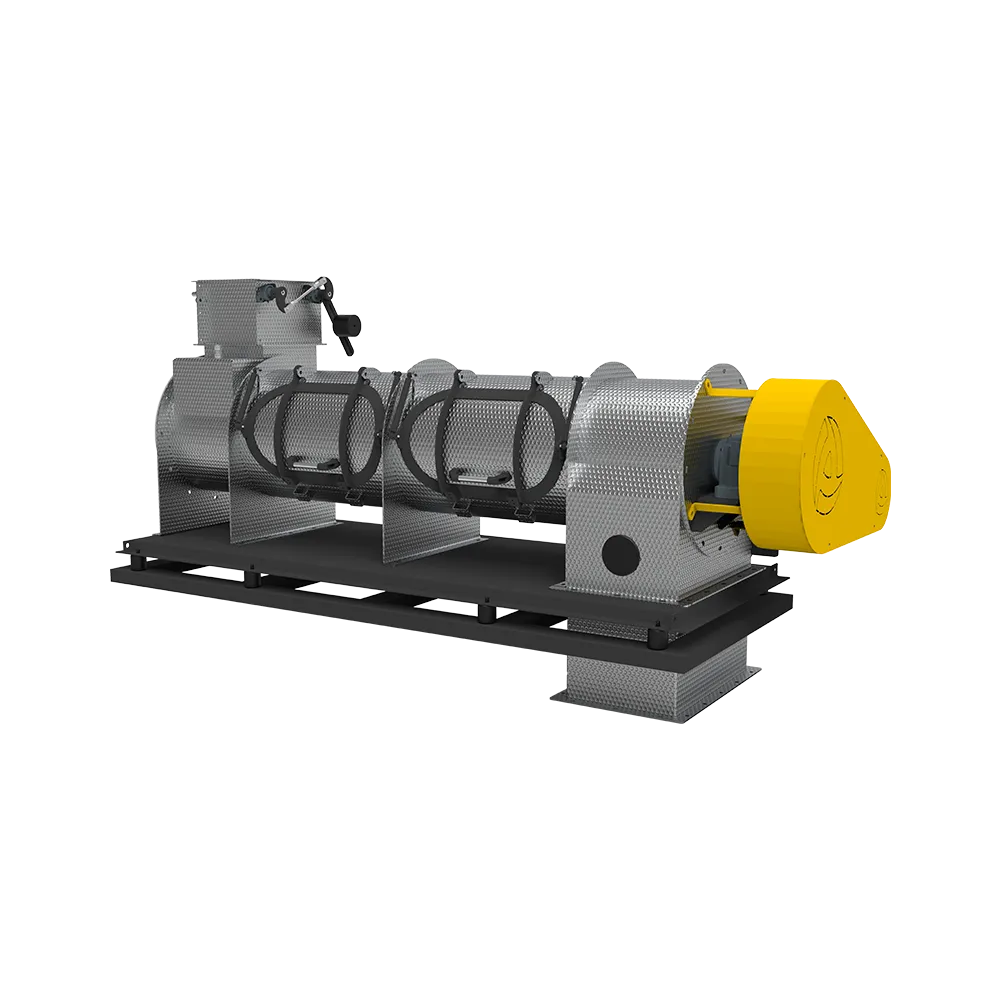

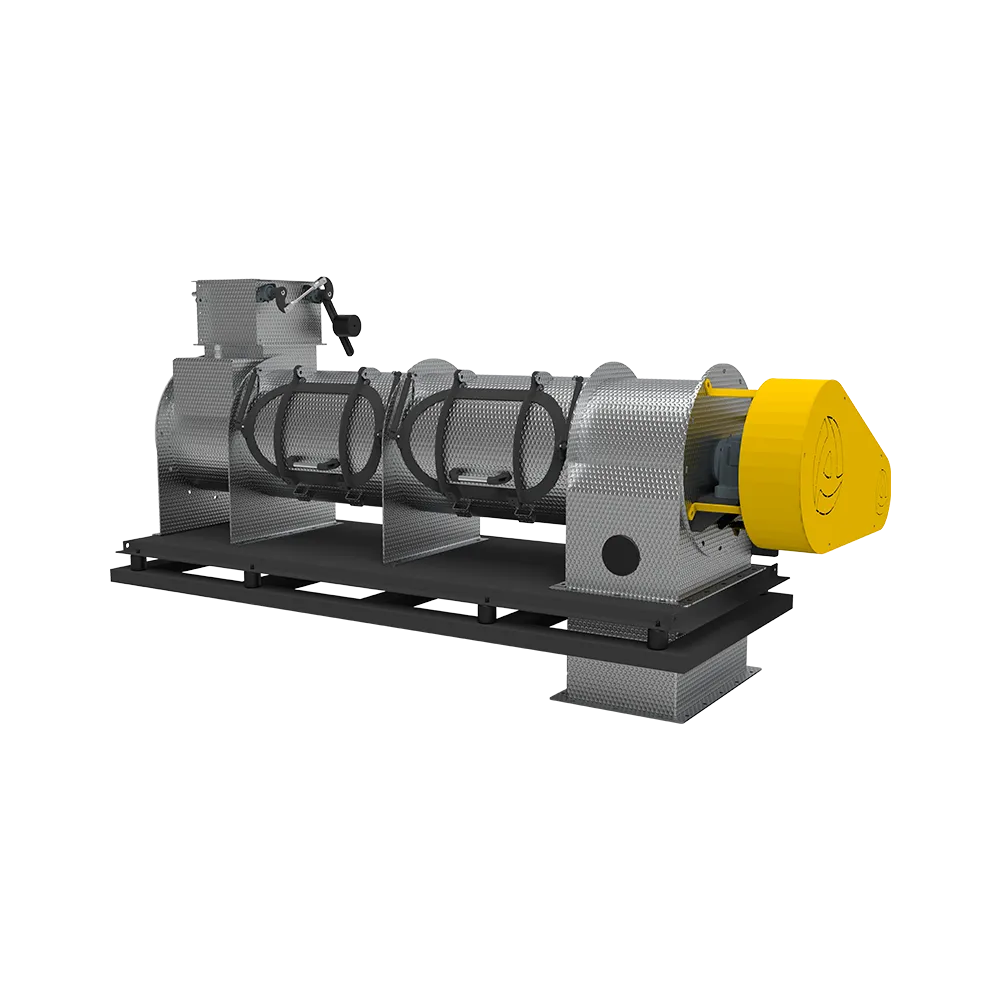

The most critical stage of a feed production line is the precise merging of all ration components. Atlas Yem mixing systems guarantee an equal distribution of every particle, from micro-ingredients to bulk raw materials. In modern livestock farming, efficiency depends on every single pellet or mash feed carrying the exact same nutritional value. Atlas Yem technology transforms this high standard into reality with a remarkably low Coefficient of Variation (CV).

Why Choose Atlas Yem Mixer Technologies?

Establishing the balance between speed and precision in industrial mixing processes requires superior engineering. Our product range, including horizontal mixers, twin-shaft paddle mixers, and ribbon mixers, is optimized for the specific needs of facilities with varying capacities. While aiming for maximum tonnage with short mixing cycles, our gentle paddle designs prevent damage to the raw material's structure, preserving product integrity. Furthermore, our liquid injection-ready housing ensures additives like oil and molasses are integrated without clumping.

Operational Power and Technical Superiority

Atlas Yem feed mixers are more than just mixing tanks; they are long-term investment assets. Pneumatically controlled full-length discharge gates (bomb-doors) prevent cross-contamination between batches and reduce discharge time to mere seconds.

16 from the product 1–12 Showing between