Industrial Pellet Press & Feed Pelletizing Systems | Atlas Yem

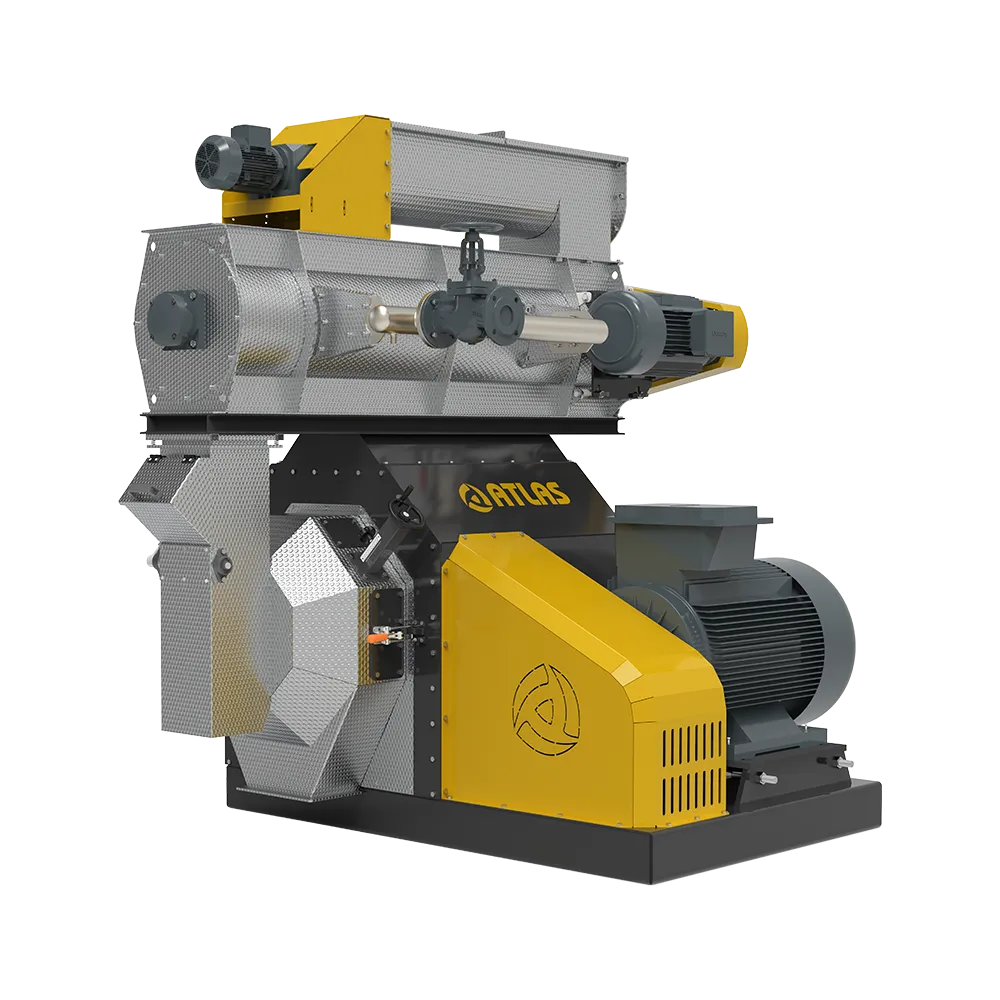

Pellet Press

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Pellet Press All Products

Atlas Yem pelletizing technology is engineered with high-torque drive mechanisms and optimized compression geometries. Our Pellet Press systems ensure maximum Pellet Durability Index (PDI) with minimal energy consumption.

Pellet Press: Industrial Authority in Feed Pelletizing Systems

In the global industrial feed sector, the Pellet Mill is the heart of production. The efficiency of a Pelletizing System determines the physical quality and nutritional availability of the feed. At Atlas Yem, we specialize in building the ultimate Feed Pelletizer solutions that focus on thermal treatment and high-pressure compaction. A professional Pellet Press does more than just shape the feed; it eliminates pathogens through heat and ensures that every pellet carries the exact nutritional value intended in the ration. By reducing fines and increasing density, our systems optimize storage and transport logistics for global feed producers.

Gear Driven Pellet Mill: The Pinnacle of Torque and Efficiency

For large-scale operations, the Gear Box Pellet Press is the industry standard for durability. Our Gear Driven Pellet Mill models offer superior power transmission compared to traditional belt-driven systems. This ensures that the Feed Pellet Machine operates at peak performance even under the heavy resistance of fiber-rich or high-oil formulations. By reducing power loss, we help producers lower their operational expenses (OPEX) per ton of feed produced. Every unit is reinforced with heat-treated alloy dies to withstand 24/7 heavy-duty industrial cycles.

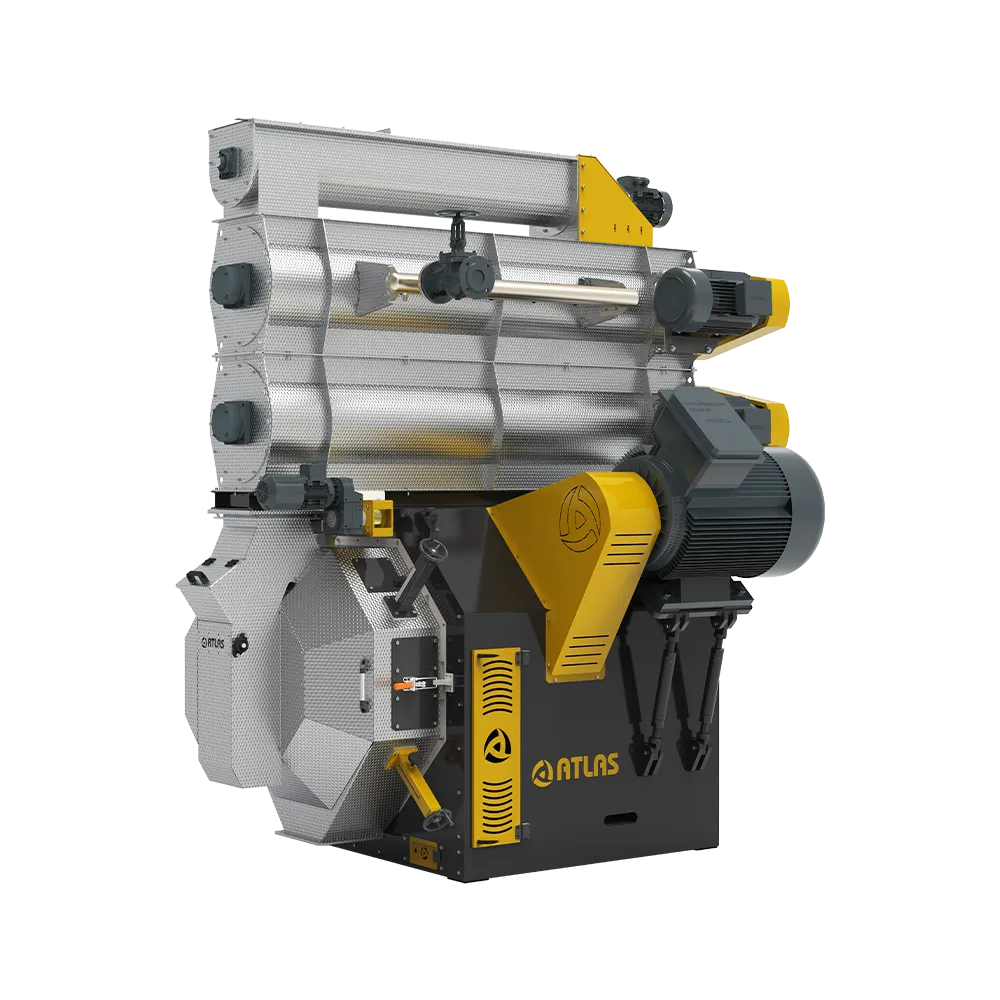

Poultry Feed and Cattle Feed Pelletizing Excellence

Atlas Yem provides specialized solutions tailored to different animal species. Whether you are looking for a Poultry Feed Pellet Machine designed for rapid throughput and optimal starch gelatinization, or a Cattle Feed Pellet Mill capable of handling dense ruminant rations, our engineering is optimized for your specific needs.

-

Chicken Feed Pelletizer: Focused on hygiene and consistent particle size for starter and finisher feeds.

-

Aquatic and Pet Food: High-precision machines for floating or sinking fish feed and high-density pet food kibbles.

-

Conditioning Excellence: Every system is equipped with an advanced Feed Conditioner or Steam Conditioner to ensure the mash reaches the correct temperature for hygiene and durability.

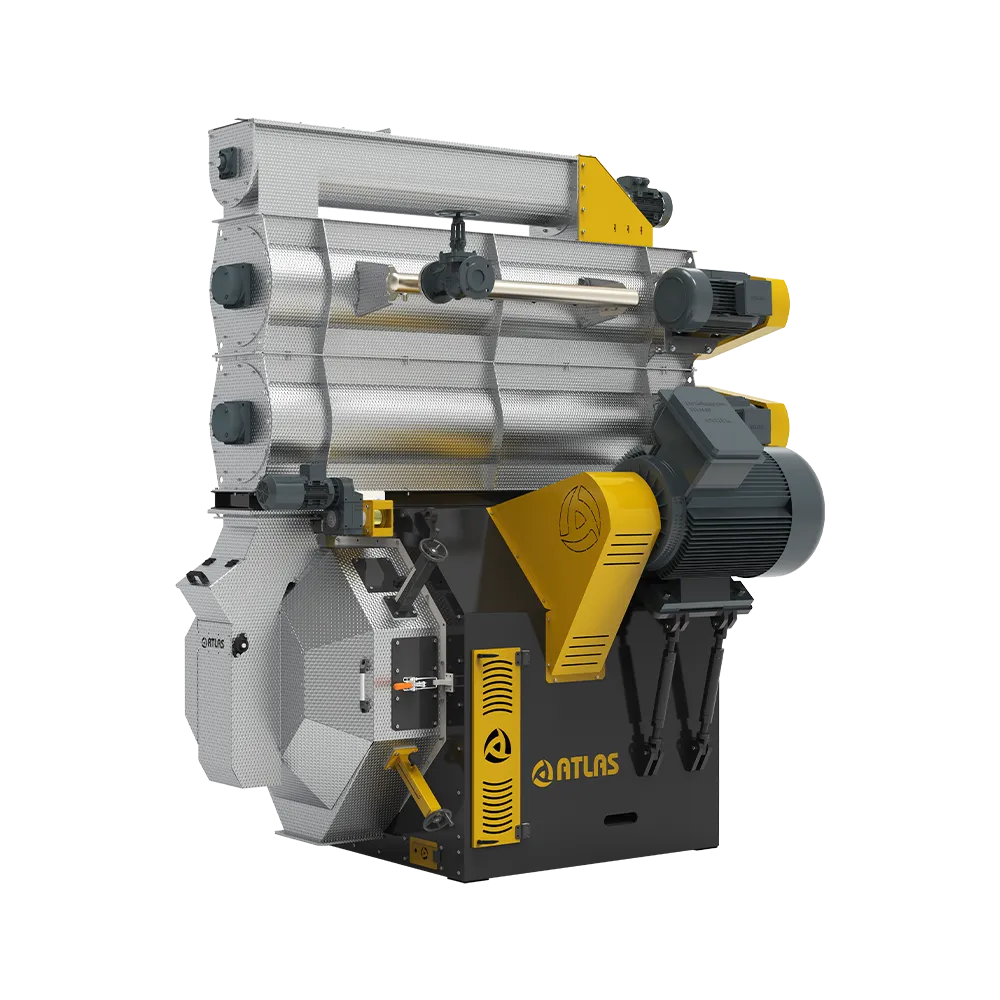

Operational Stability and Long-Term Durability

The longevity of a Pelletizing System depends on the quality of its wear parts and the robustness of its main frame. Atlas Yem utilizes heavy-duty rollers and precision-drilled dies to ensure our machines withstand the mechanical stress of continuous production. Our commitment to engineering excellence means less downtime and more consistent production for your facility.

Technical Features of Atlas Pellet Press Systems

-

Advanced Steam Conditioning: Stainless steel Steam Conditioner for optimal starch gelatinization and pathogen control.

-

High PDI Guarantee: Engineering designs that ensure minimal fines and maximum pellet durability.

-

Automation Integration: Fully compatible with modern PLC systems for smart load management and roller adjustment.

-

Heavy-Duty Construction: Reinforced steel body designed for extreme mechanical stress and vibration-free operation.

-

Global Spare Part Support: Reliable supply of high-quality dies and rollers for long-term operational security.

7 from the product 1–7 Showing between