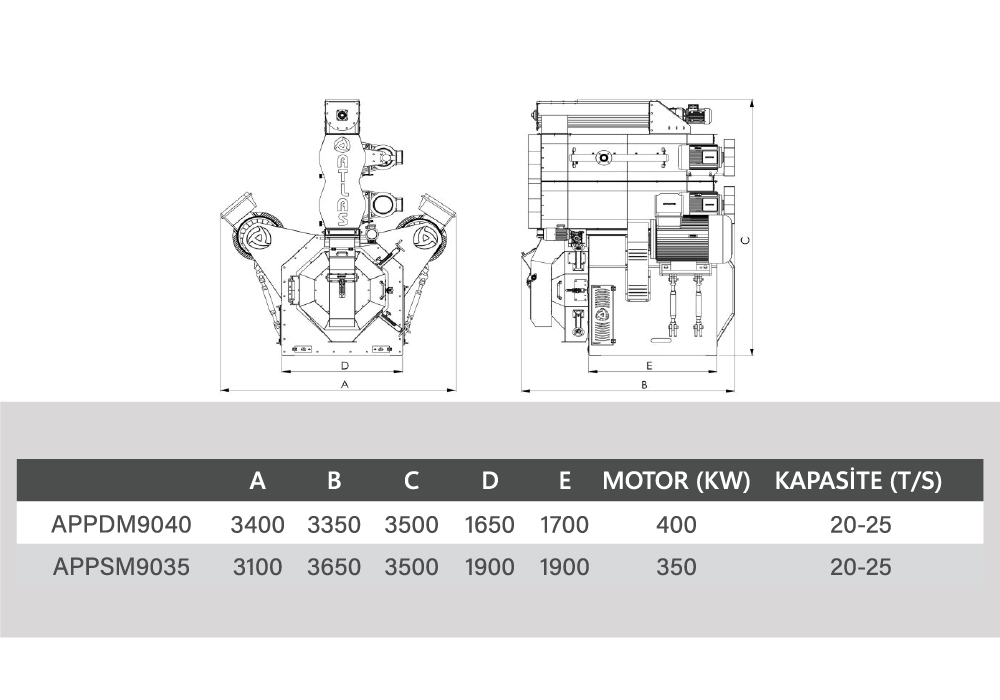

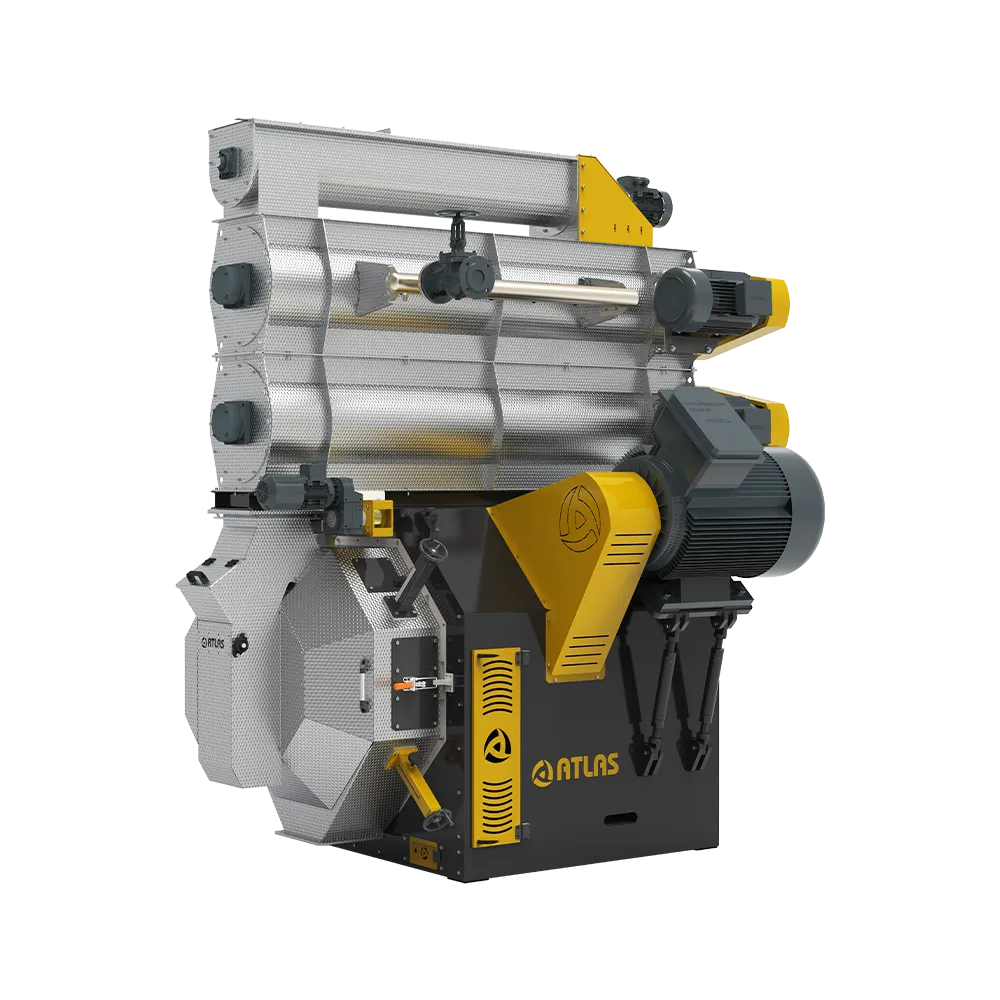

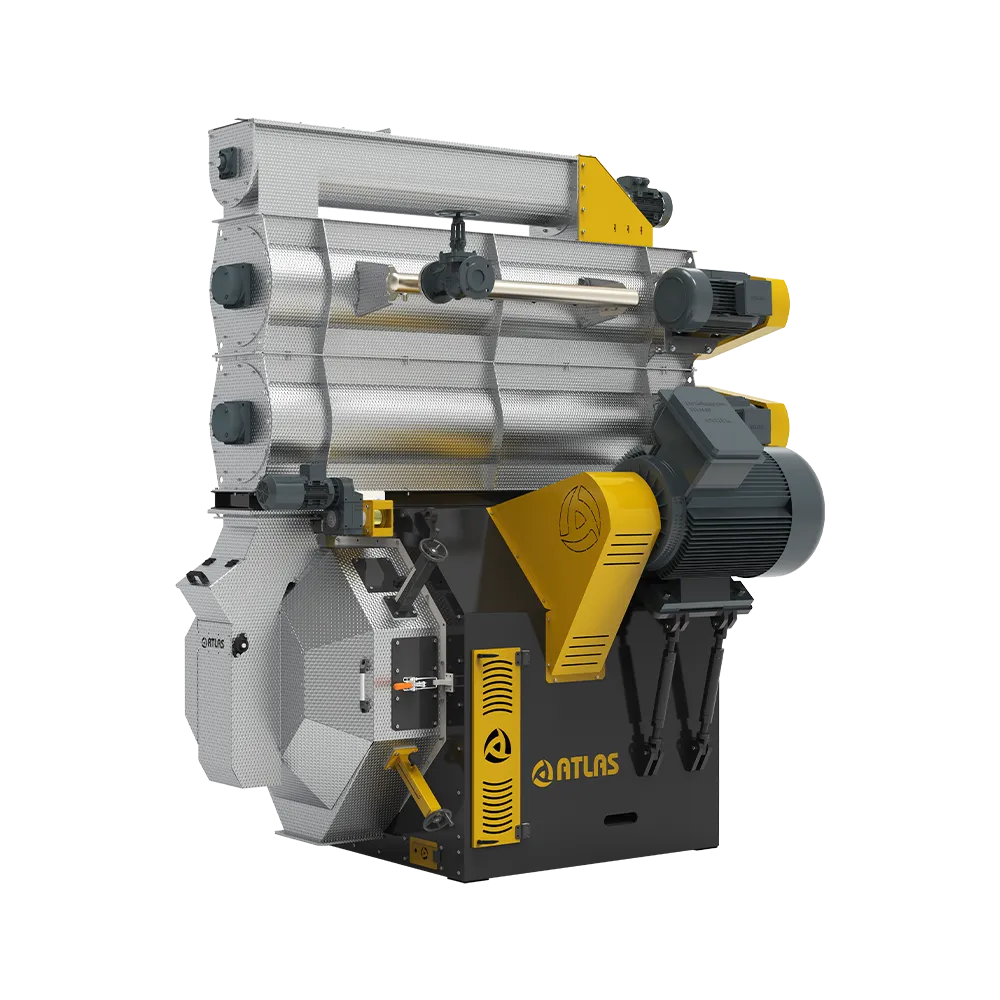

Pellet Press APPDM9040 | Industrial Feed Pelletizing System

APPDM9040

APPDM9040

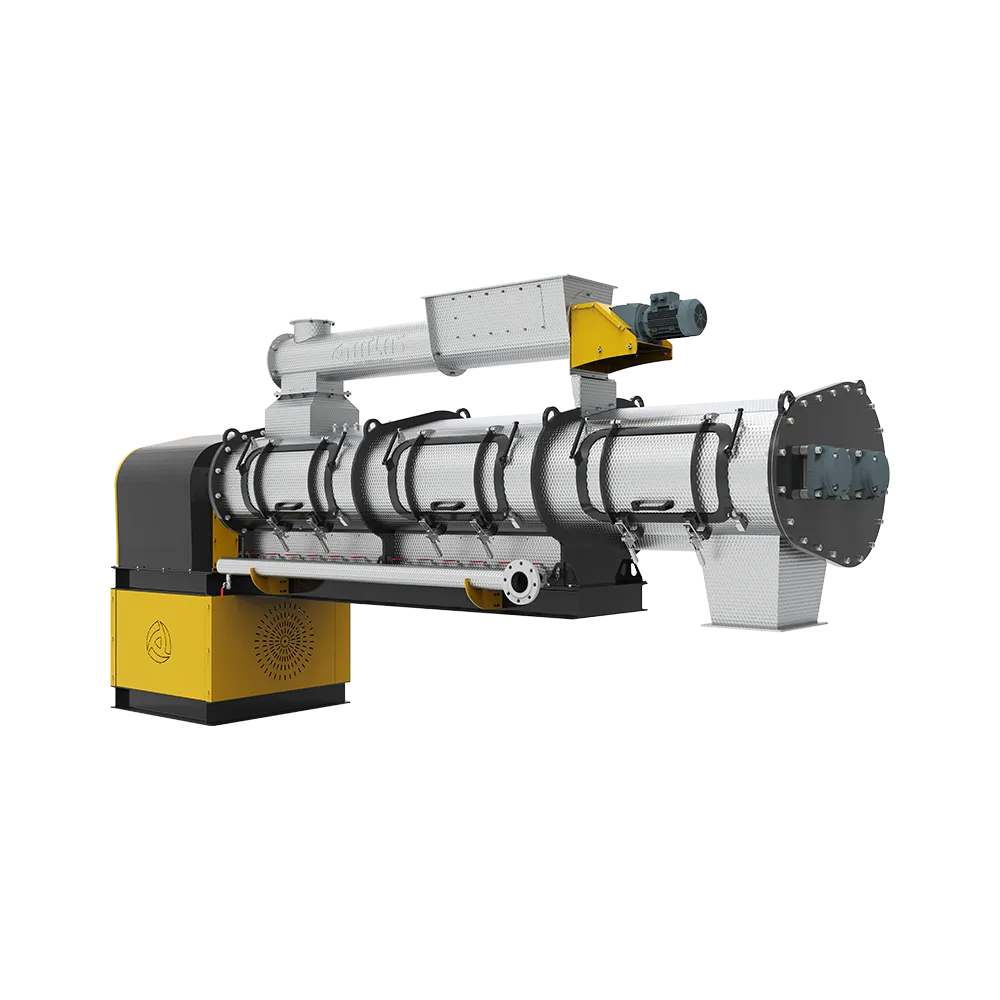

Pelletizing requires just the right combination of force, humidity and temperature to achieve the perfect consistency. Our ability to achieve this perfect combination comes from configuring the right equipment in your processing line. Atlas Feed Milling Technology pelletizing solutions think of everything for you, from conditioning to cooling, to turn your resources into perfect pellets.

APPDM9040 Pellet Press: Industrial Excellence in Feed Production

In the global industrial sector, the Pellet Mill is the heart of any feed plant. The APPDM9040 Pellet Press is the most vital stage in the feed production line, engineered to optimize energy utilization and maximize product density. Pelletizing facilitates the extraction of maximum nutritional value from plant-based raw materials while significantly reducing transportation volume and minimizing storage and logistics costs.

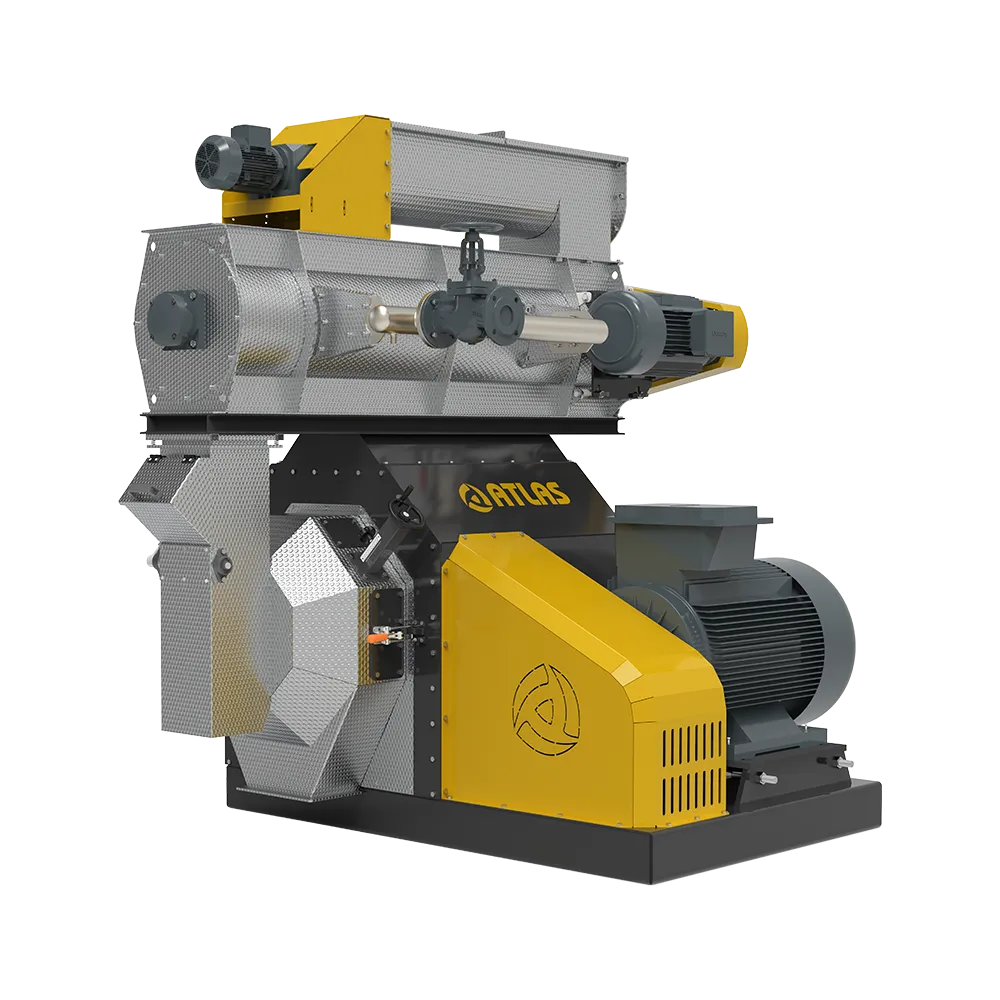

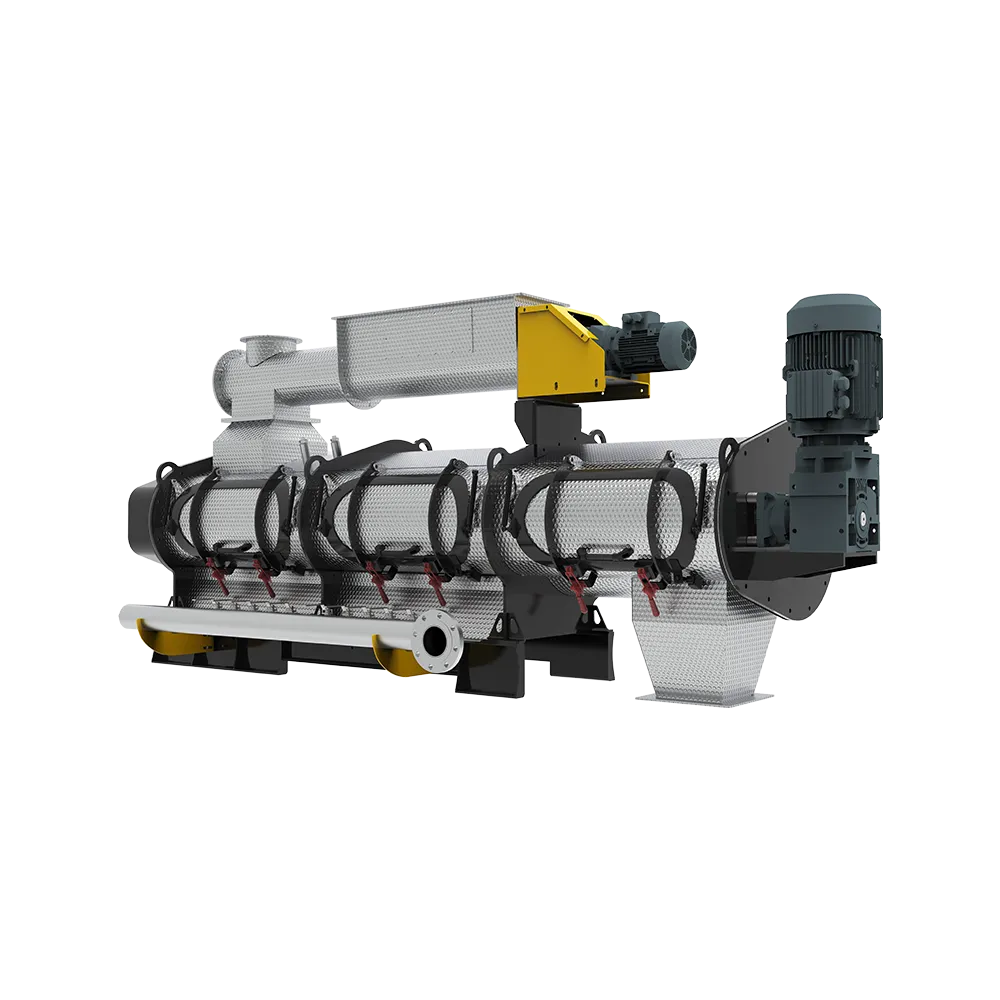

Three Core Engineered Components: Feeder, Conditioner, and Press

The APPDM9040 Feed Pelletizer is built on a foundation of precision, consisting of three primary sections. The FEEDER ensures an accurate and consistent flow of raw materials. The Steam Conditioner (Conditioner) provides critical thermal treatment, ensuring the mash reaches optimal temperatures for starch gelatinization and pathogen elimination. Finally, the PRESS unit compacts the conditioned material under extreme pressure into high-quality, durable pellets.

Optimized for Poultry, Cattle, and Specialty Rations

Whether you require a high-capacity Poultry Feed Pellet Machine or a heavy-duty Cattle Feed Pellet Mill, the APPDM9040 delivers a superior Pellet Durability Index (PDI). Our technology is adaptable for various applications, including Chicken Feed Pelletizer systems and specific lines like sunflower meal pelletizing. By focusing on thermal stability and mechanical precision, we ensure that every pellet maintains its integrity from the factory to the feeder.

Operational Stability and Energy Efficiency

Energy consumption per ton is a critical KPI for modern manufacturers. The APPDM9040 Gearbox Pellet Press design (optional) or high-efficiency pulley systems provide maximum torque with minimal power loss. This robust Feed Pellet Machine is designed for 24/7 industrial cycles, featuring reinforced frames and heat-treated wear parts to reduce operational expenses (OPEX) and ensure long-term ROI.