Feed Conditioners & Steam Conditioning Systems | Atlas Yem

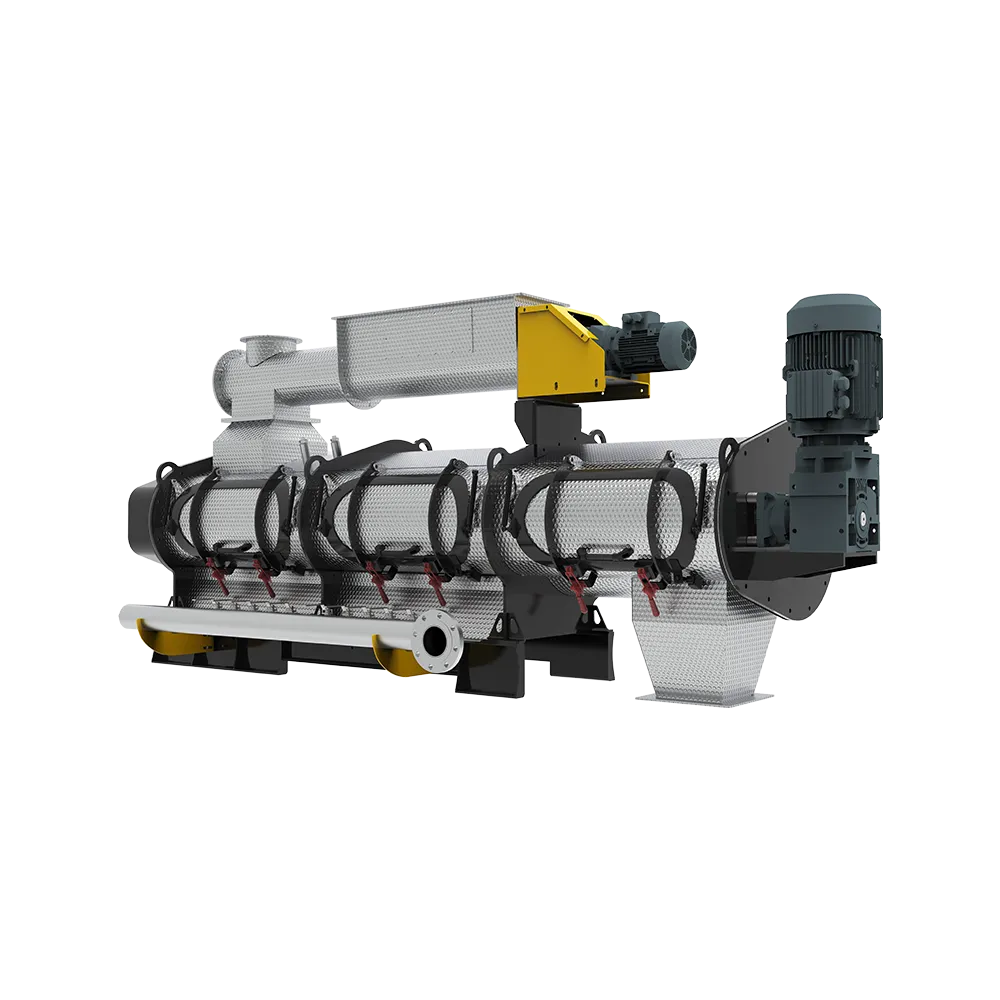

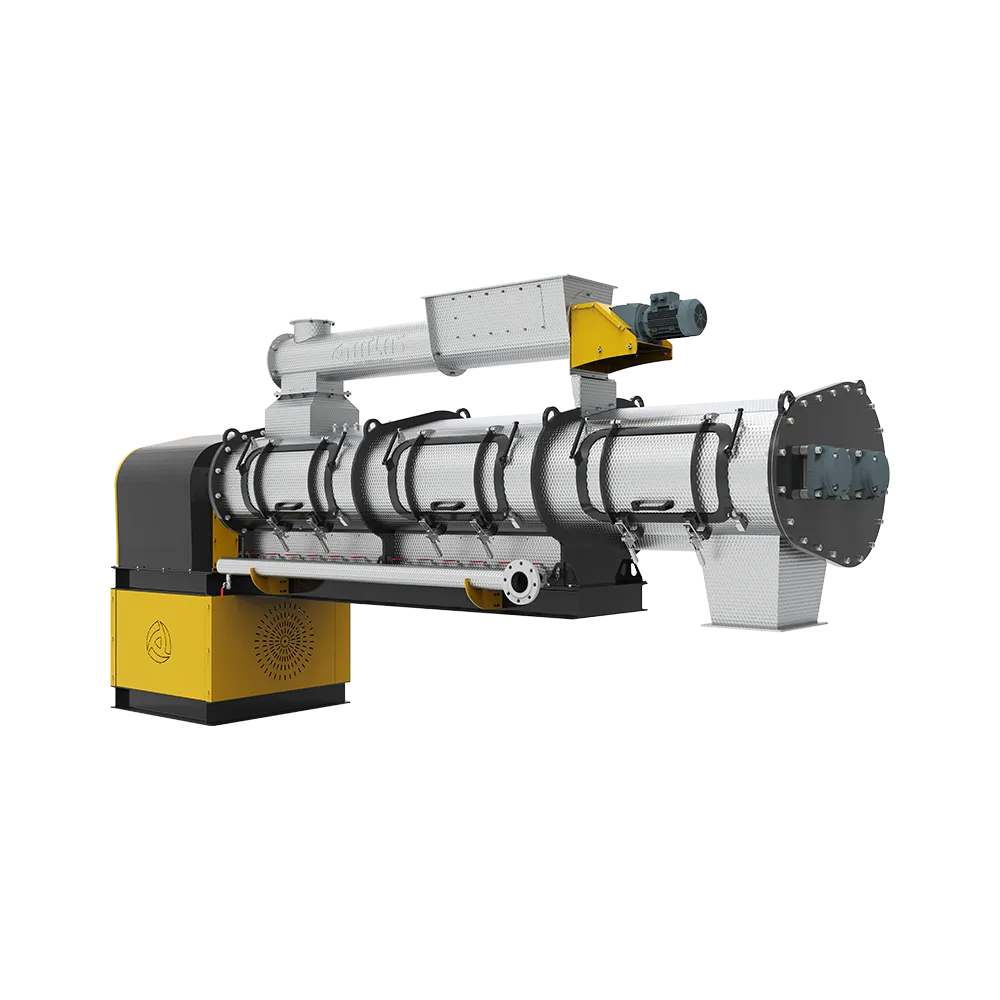

Conditioner

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Conditioner All Products

The Architect of Pellet Quality: Conditioning Technology

In a feed production line, conditioning is the most strategic stage where raw materials undergo physical changes via steam and heat before entering the pellet press. Atlas Yem conditioner systems precisely manage the moisture and temperature balance of the mash feed, maximizing pelleting efficiency. A proper steam conditioning process not only improves the Pellet Durability Index (PDI) but also significantly reduces energy consumption.

Starch Gelatinization and Nutritional Optimization

The feed conditioner units engineered by Atlas Yem facilitate the gelatinization of starch within the raw material. This process enhances the digestibility of the feed, directly contributing to animal performance. Furthermore, the high-temperature hygienization process eliminates pathogens in the feed, ensuring the highest standards of biological safety.

Technical Advantages and Variations

-

Material Durability: Full stainless steel (AISI 304/316) construction resistant to wear and corrosion.

-

Precision Steam Injection: Multi-point steam inlets for uniform conditioning across the product.

-

Adjustable Paddles: Angled paddles to optimize the retention time of the feed.

-

Model Diversity: Single, double, and long-term retention conditioner configurations for various industrial needs.

4 from the product 1–4 Showing between