ASSD20 Conditioner | Industrial Feed Steam Conditioning

ASSD20

ASSD20

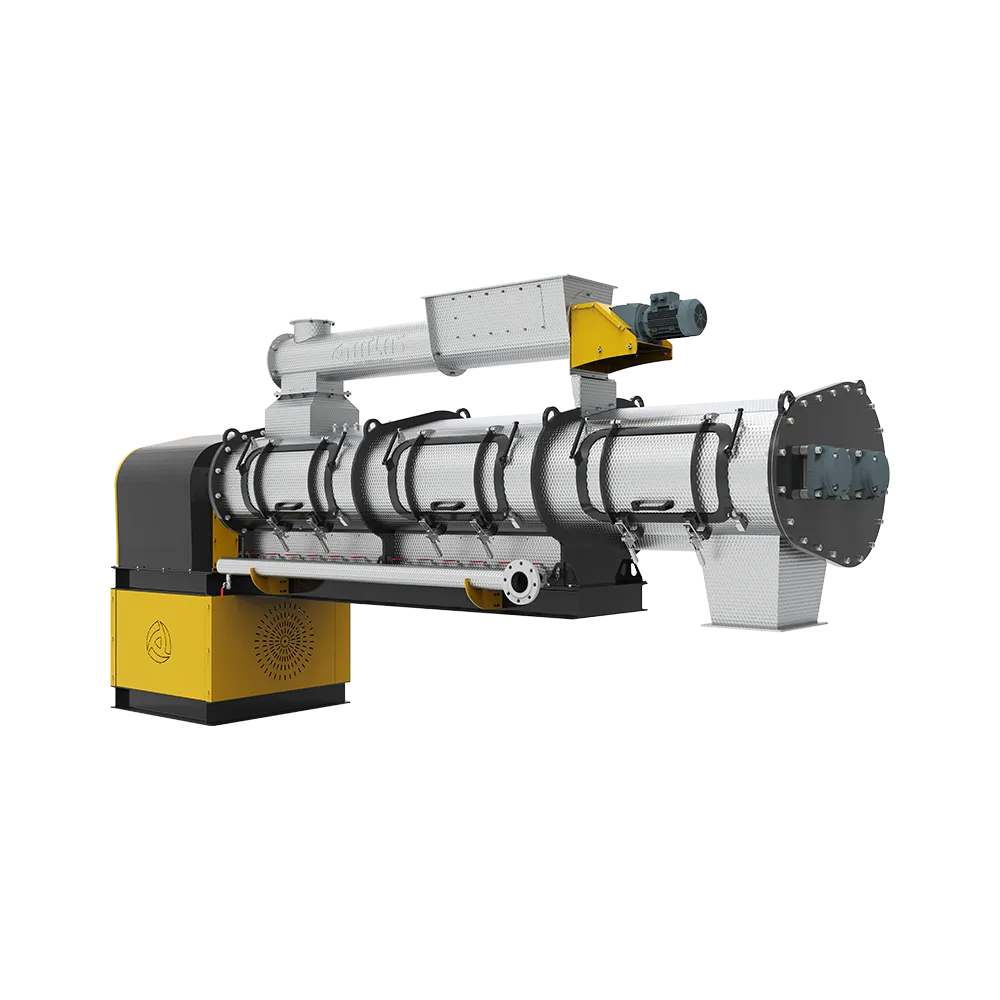

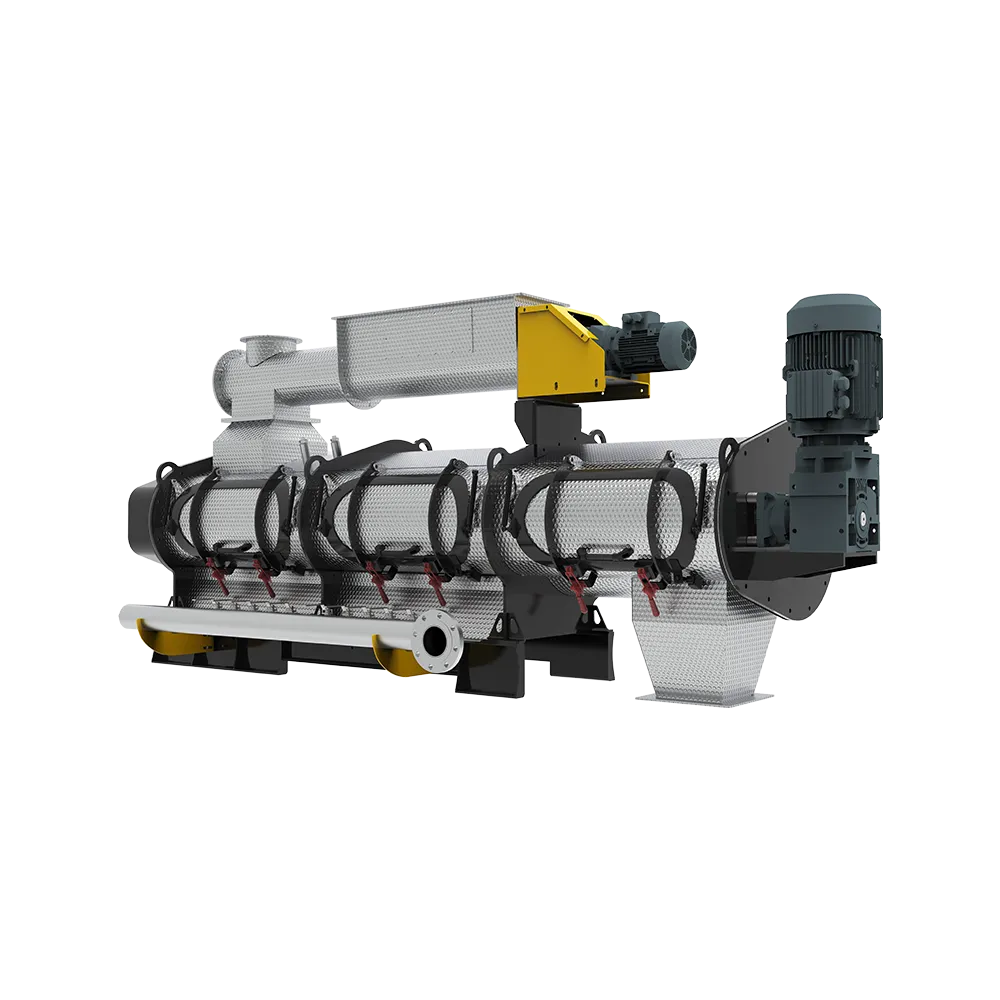

The ASSD20 provides high-precision annealing of semi-finished products with steam before the pelletizing process. It ensures a perfectly homogeneous mix with liquid enzyme and molasses additives for high-quality industrial output.

Excellence in Feed Conditioning with ASSD20 Technology

Conditioning is the cornerstone of high-quality industrial pellet production and overall feed efficiency. The Atlas Yem ASSD20 Conditioner is specifically engineered to provide superior steam annealing of semi-finished products before they enter the pellet press. This process is vital for achieving optimal starch gelatinization and effective hygienization of the feed, ensuring pathogen elimination. With its advanced liquid supplement nozzles, additives such as molasses and enzymes are integrated into the mash with perfect homogeneity, significantly enhancing the nutritional availability and animal performance of the final ration.

The ASSD20 features a robust dual-shaft mechanism where shafts of different diameters and speeds rotate in opposite directions. This specific engineering ensures that the materials, steam, and liquids intersect completely for a thorough thermal and physical mix. Offering a retention time of up to 180 seconds, it ensures a high cooking degree and liquid stability for the product. Manufactured from premium AISI304 stainless steel, the ASSD20 provides a stable, energy-efficient, and reliable performance for heavy-duty feed production plants. By optimizing the product state before pelleting, it reduces wear on the pellet mill dies and enhances the Pellet Durability Index (PDI). This system is the ideal choice for modern facilities aiming for maximum operational excellence.