ADC30 Conditioner | Industrial Feed Steam Conditioning Systems

ADC30

ADC30

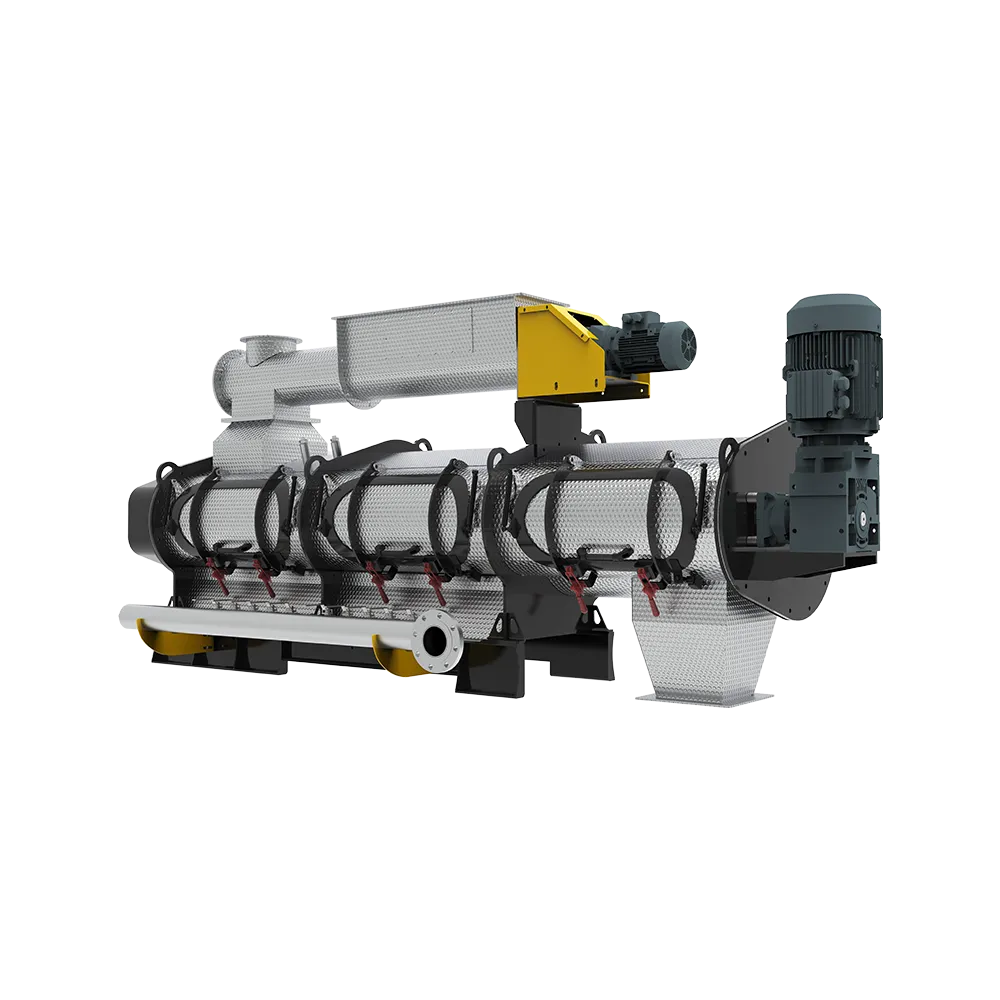

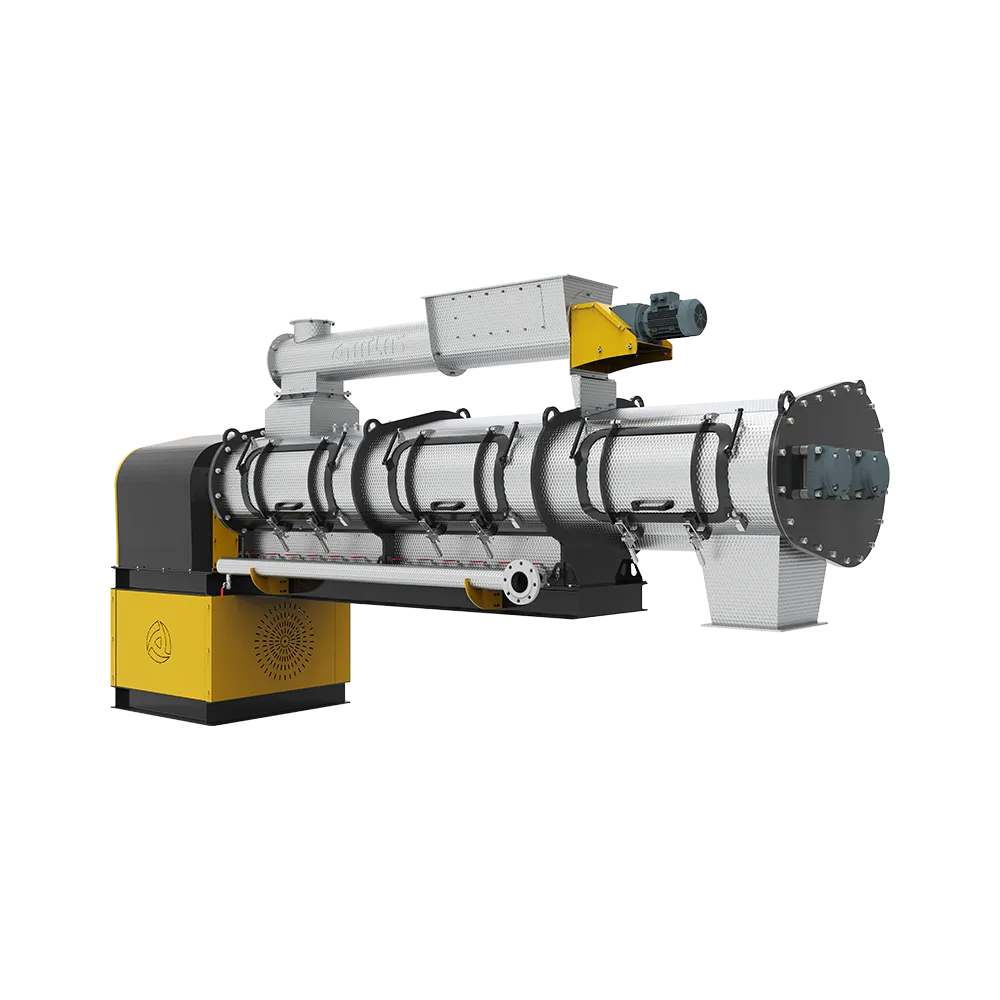

ADC30 provides professional steam annealing of semi-finished products before pelletizing. It ensures a perfectly homogeneous mix with liquid enzyme and molasses additives for high-quality output.

Excellence in Feed Conditioning with ADC30 Technology

Conditioning is the cornerstone of high-quality industrial pellet production. The Atlas Yem ADC30 Conditioner is engineered to provide superior steam annealing of semi-finished products before they enter the pellet press. This process is vital for achieving optimal starch gelatinization and effective hygienization of the feed. With its advanced liquid supplement nozzles, additives such as molasses and enzymes are integrated into the mash with perfect homogeneity, significantly enhancing the nutritional availability of the final ration.

The ADC30 features a dual-shaft mechanism where shafts of different diameters rotate in opposite directions. This specific movement ensures that the materials, steam, and liquids intersect completely for a thorough mix. Offering a retention time of up to 180 seconds, it ensures a high cooking degree and liquid stability for the product. Manufactured from premium AISI304 stainless steel, the ADC30 provides a stable, energy-efficient, and reliable performance for heavy-duty feed production plants, minimizing maintenance while maximizing the output quality of the entire Pelletizing System.