AMMSS10 Melassier | High-Capacity Molasses Mixing | Atlas Yem

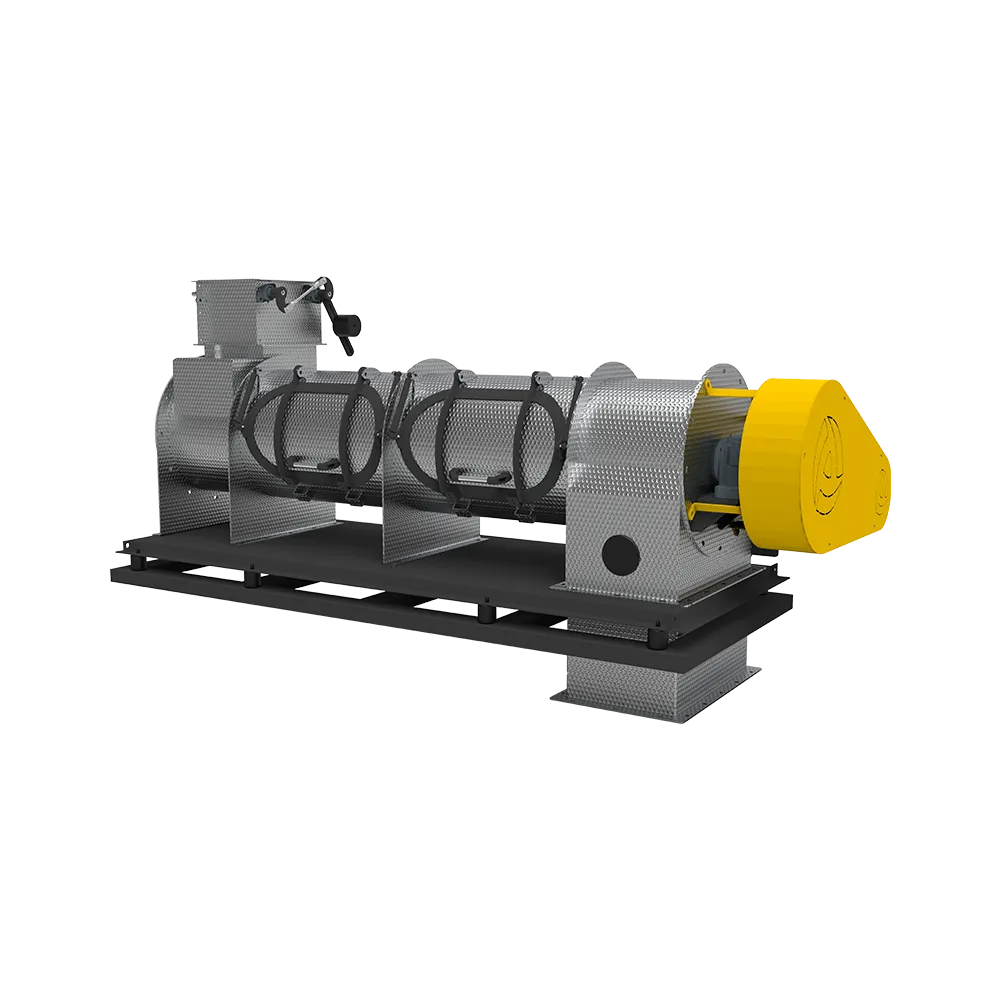

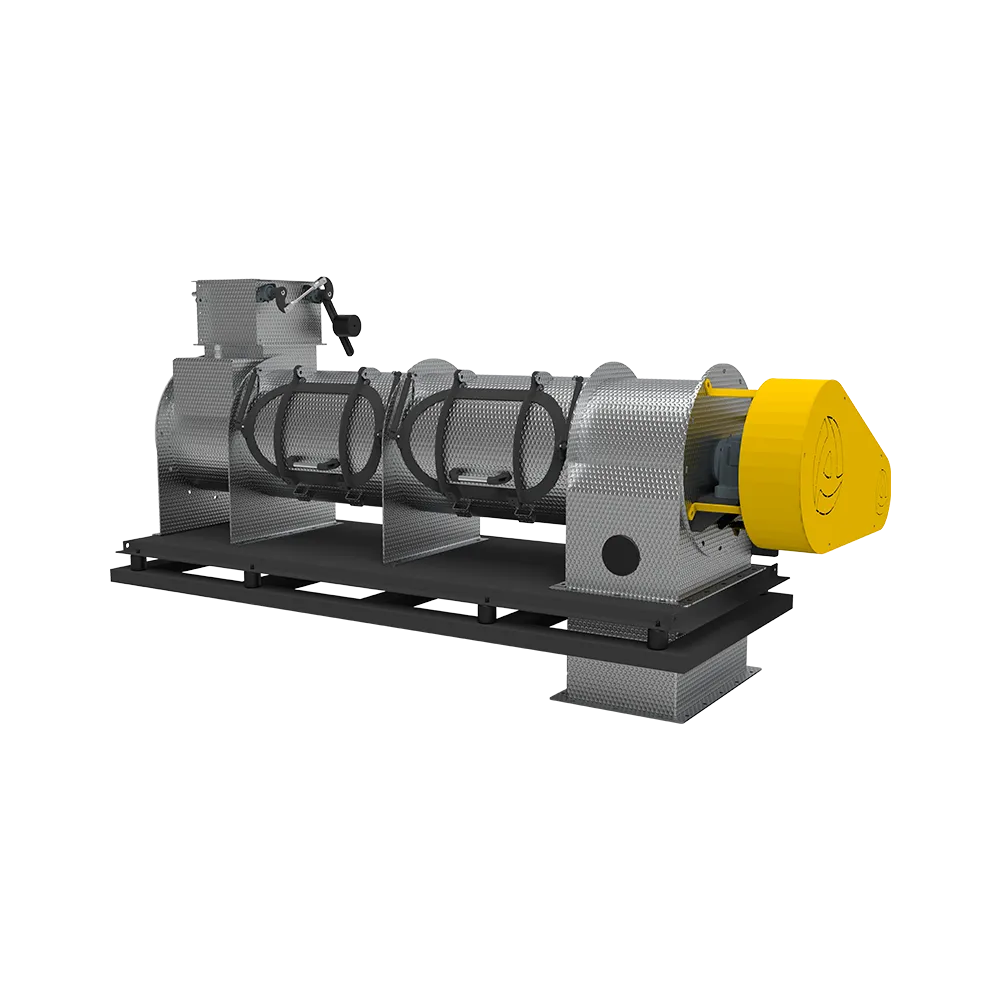

AMMSS10

AMMSS10

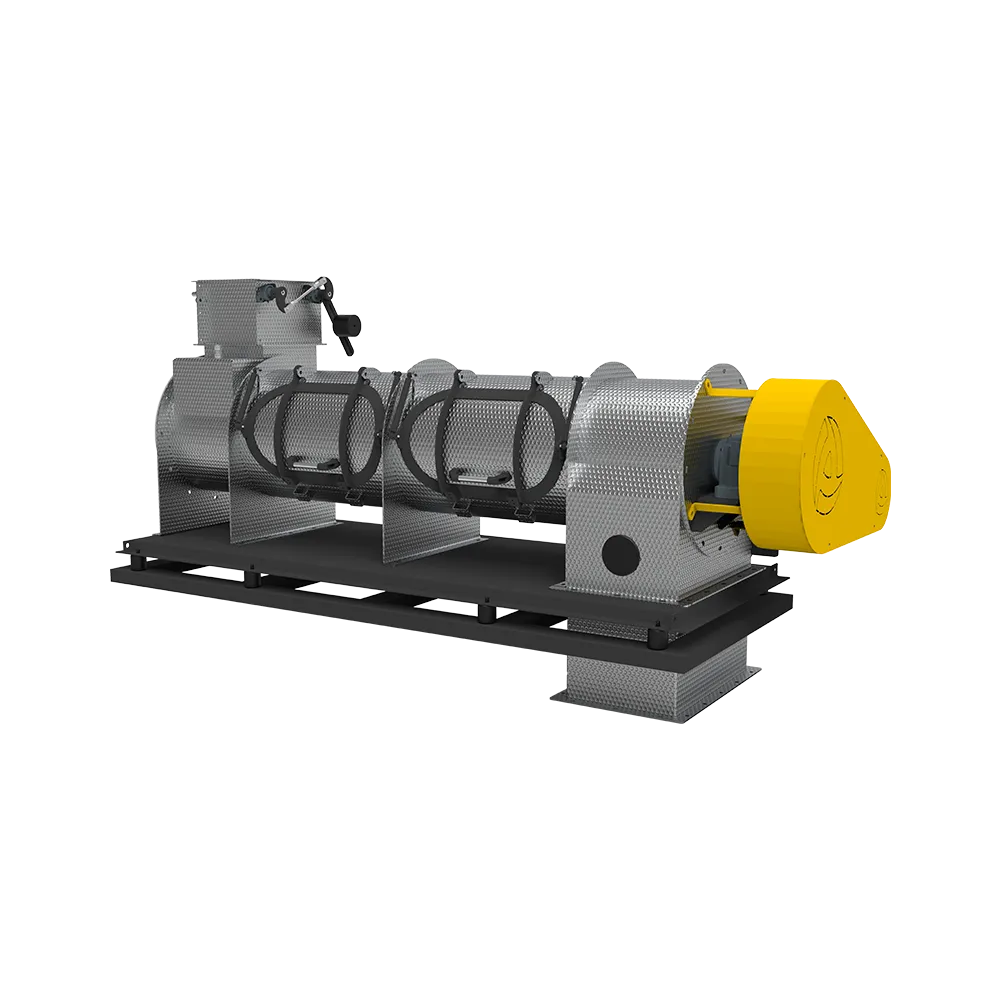

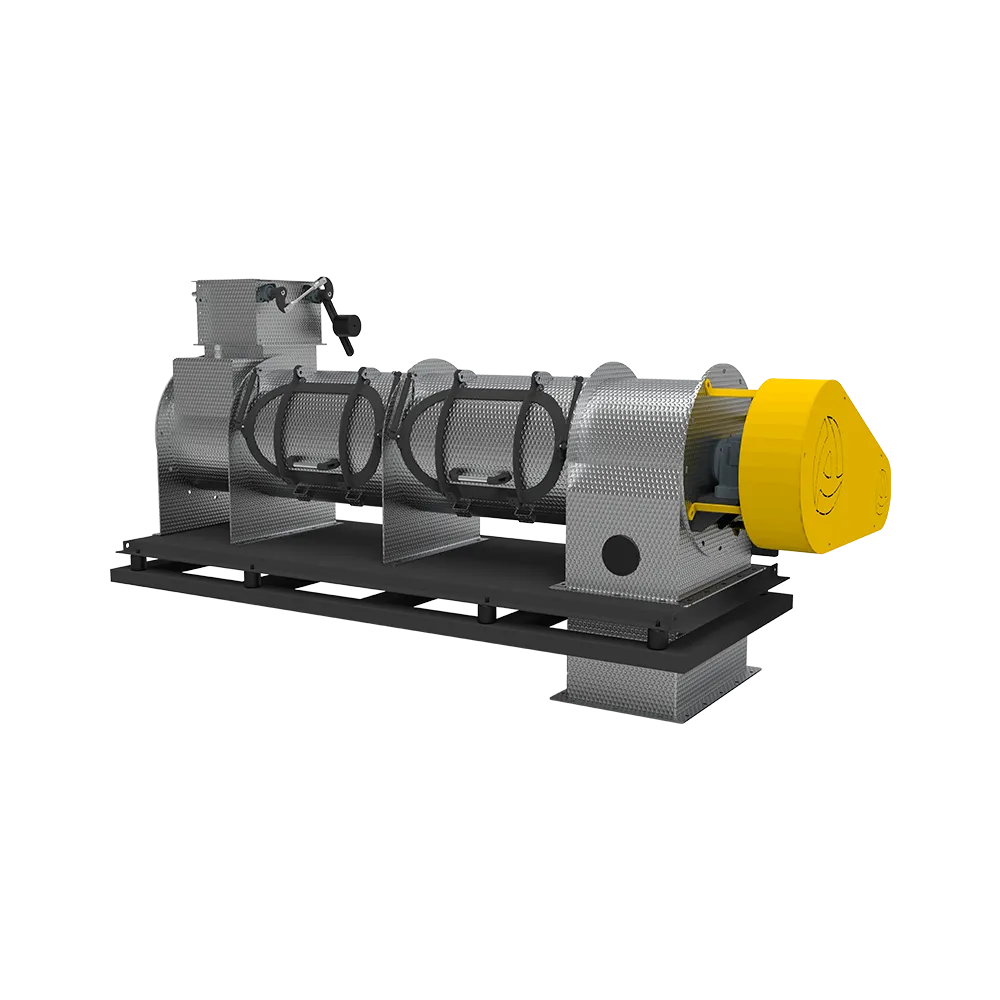

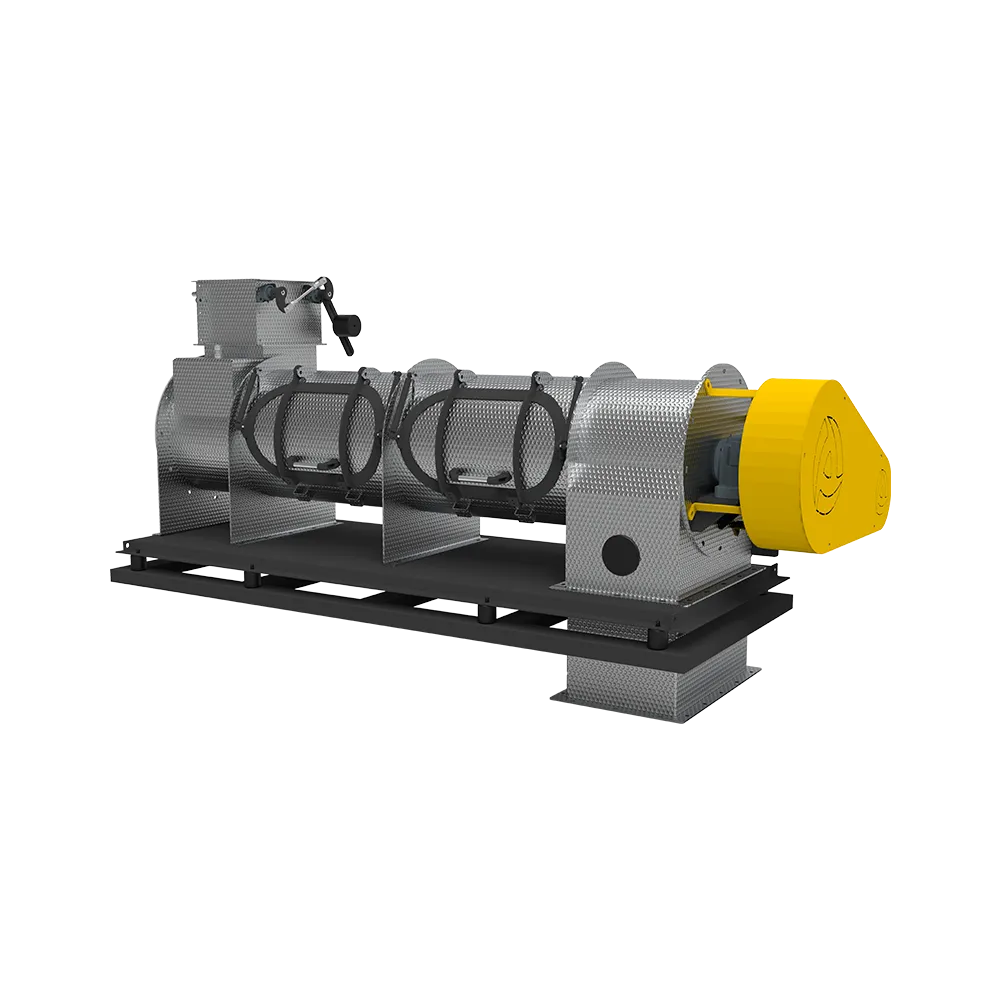

The AMMSS10 is a high-capacity industrial mixing unit specifically engineered for preparing energy-dense feed rations. By ensuring that semi-feed products are blended homogeneously with sugary liquids (molasses) and other essential additives, it makes the product ready for the next production stage in seconds. Developed with Atlas Yem's advanced engineering, this system is a vital component for standardizing the nutritional value and palatability of your premium feed products.

In modern feed manufacturing, integrating molasses into the ration poses significant risks like clumping and machinery blockage if total homogeneity is not achieved. The AMMSS10 Melassier eliminates these risks through its high-speed rotor technology and precision-angled paddles. It ensures that every particle of the raw material is coated with a fine layer of liquid, delivering superior mixing quality and better pellet durability.

The optional polymer inner lining prevents sticky residues from building up, accelerating material flow and enhancing overall corrosion resistance. Operating on a continuous mixer principle, the AMMSS10 directly supports high-tonnage production targets with its robust structure and high-level safety protocols. Designed with the philosophy of "minimum maintenance, maximum hygiene," this unit elevates your ration efficiency beyond industrial standards, making it a cornerstone of Atlas Yem's professional feed technologies.