AMMSS05 Melassier | 5 T/H Molasses Mixer | Atlas Yem

AMMSS05

AMMSS05

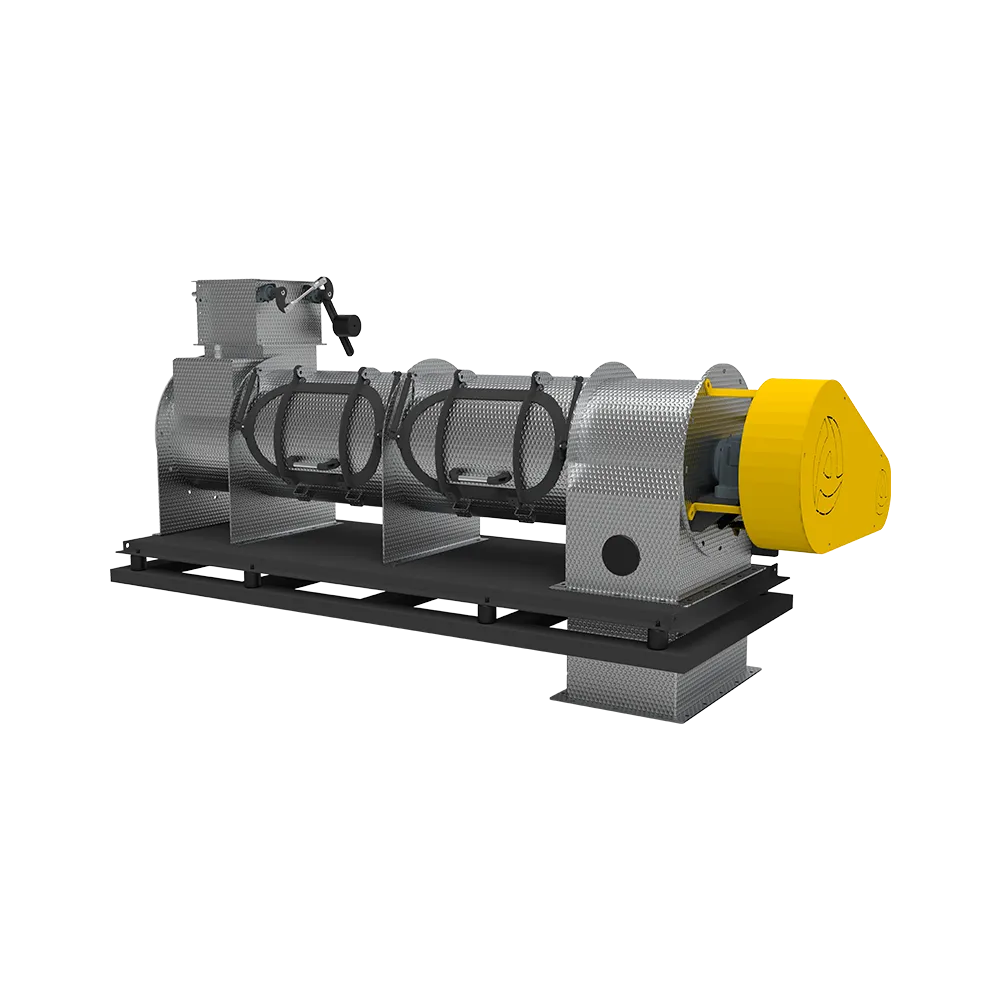

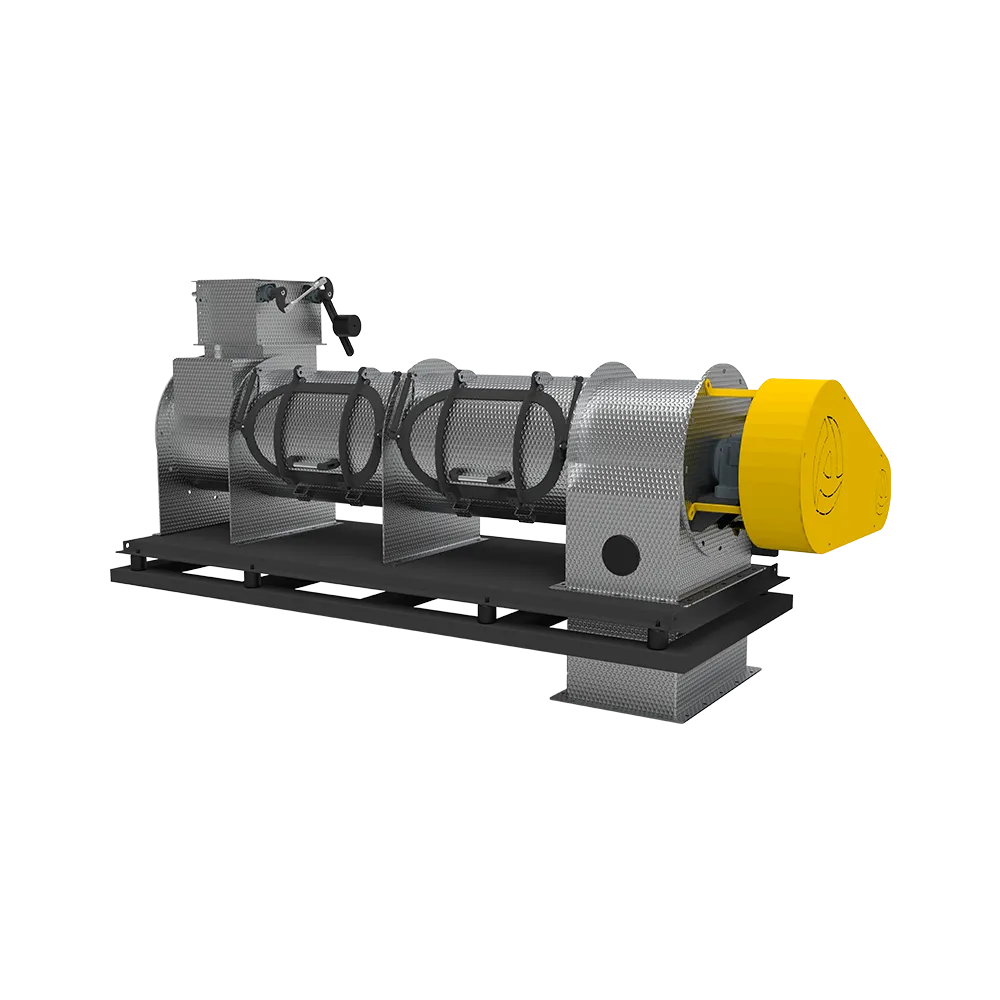

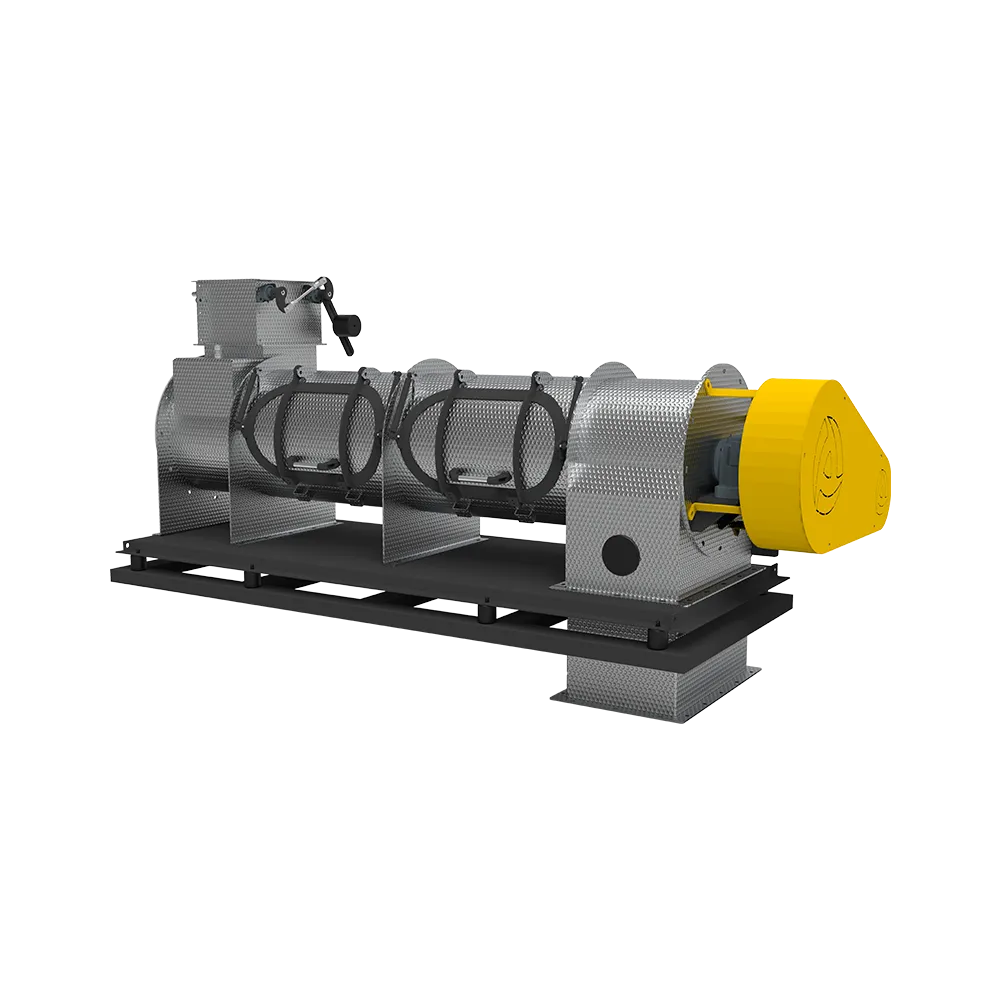

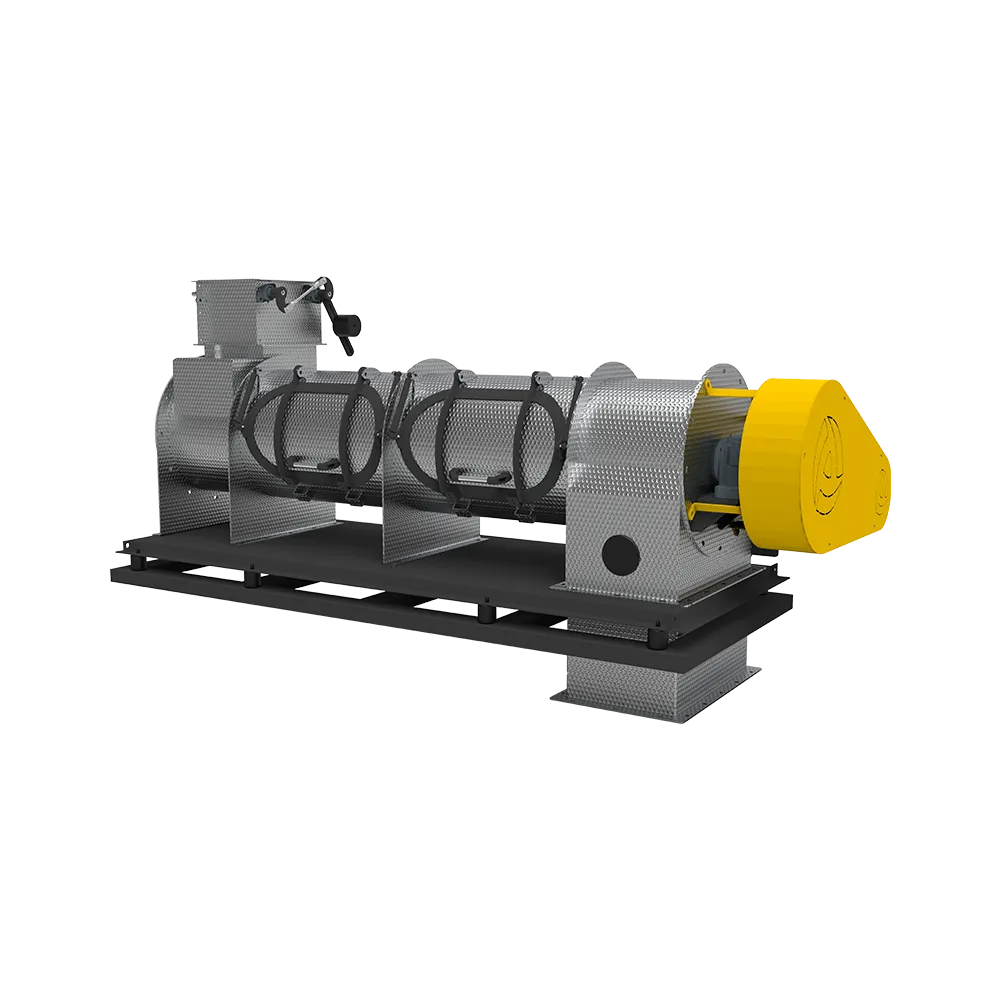

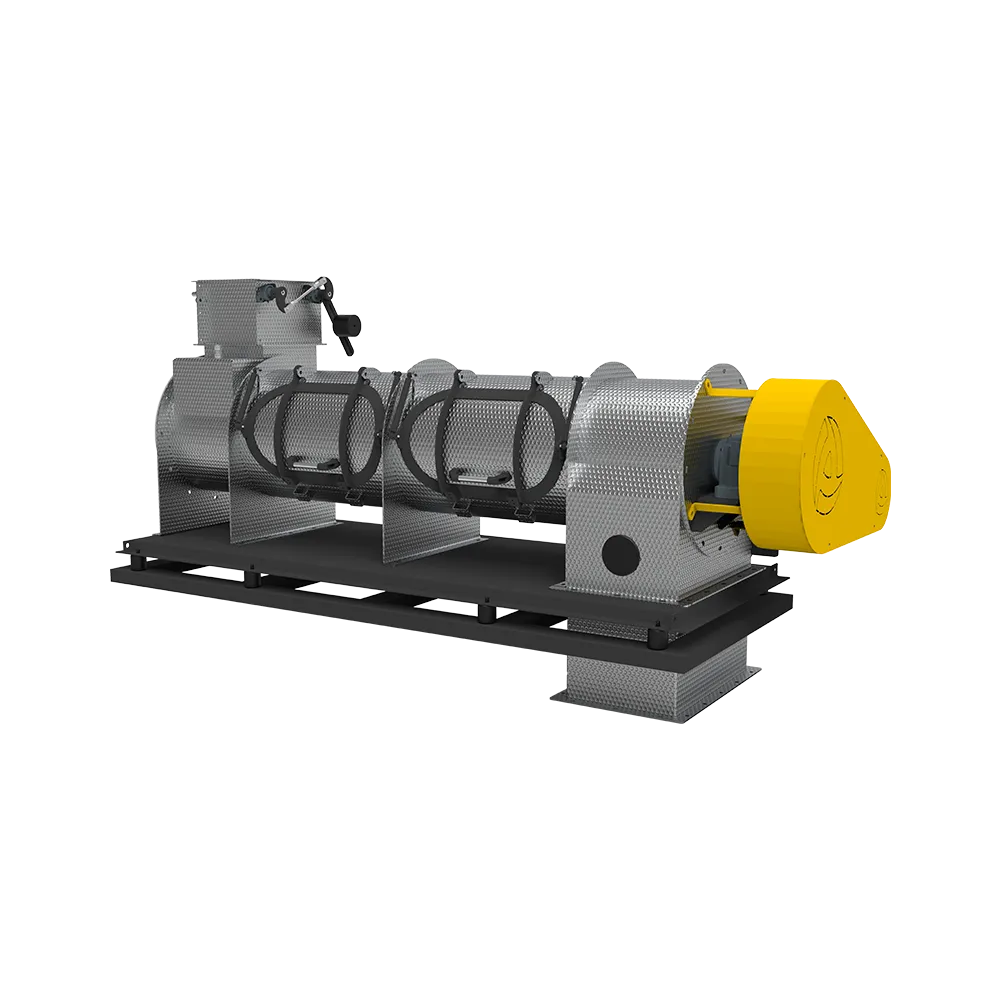

The AMMSS05 is a sophisticated mixing solution engineered to ensure that semi-feed products are blended with sugary liquids, such as molasses, with absolute industrial precision. Powered by a high-torque 11 KW motor and boasting a consistent throughput of 5 tons per hour (5 T/H), it is designed to meet the rigorous demands of modern feed technologies. This system optimizes the energy value of the feed by coating each particle homogeneously, enhancing both palatability and subsequent pellet quality. At Atlas Yem, the AMMSS05 is built to transform liquid inclusion from a process bottleneck into a competitive advantage. Its high-velocity rotor design ensures rapid dispersion of viscous additives, maintaining the structural integrity of the feed while maximizing nutritional consistency across every batch produced.

In high-end feed manufacturing, achieving 100% homogeneity is the definitive standard for quality. The AMMSS05 Melassier facilitates the seamless integration of molasses and other liquid additives into the feed mash within seconds, effectively preventing clumping or material buildup. By ensuring a uniform coating on every particle, it reduces friction within the pellet die, leading to significant energy savings and improved Pellet Durability Index (PDI).

Engineered for durability, the AMMSS05 offers a polymer lining option that resists corrosion and sticky residues. Its ergonomic design features large access doors for rapid hygienic maintenance, while integrated high-level safety protocols guarantee secure industrial operation. As a cornerstone of Atlas Yem's Mixing Systems, this unit provides the technical infrastructure necessary for standardized, high-energy feed production.