Screening Systems & Pellet Sieves | Atlas Yem

Screening Systems

Screening Systems - Products

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Screening Systems All Products

A superior feed production process doesn't end with mixing; it requires physical perfection of the final product. Atlas Yem screening systems act as the "quality guardian" of your production line. By effectively separating fines (dust) and oversized particles generated after pelleting or crumbling, these systems guarantee that the feed entering the bag is 100% standardized, clean, and uniform.

Industrial Separation and Fines Removal Solutions

Atlas Yem engineering offers optimized rotary screeners (rotary sieves) and vibratory screeners tailored for various granule structures and capacity requirements. These systems ensure that pellets are classified without breakage or degradation, while simultaneously recirculating separated fines back into the production loop to eliminate raw material waste. Specifically utilized after the pellet cooling process, our screening technologies preserve the PDI (Pellet Durability Index) and enable you to meet the "dust-free feed" standard that directly drives customer satisfaction.

9 from the product 1–9 Showing between

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Vibro Sieve All Products

The Vibro Sieve is a strategic separation technology used to purify pelleted or crumbled feed from unwanted dust and fines before packaging. Engineered by Atlas Yem, this system flawlessly classifies the product by size, guaranteeing the quality of the feed reaching the end-user and maintaining high PDI (Pellet Durability Index) standards.

Known in the industry as a vibrating screen or pellet screener, this unit utilizes linear vibration motors to ensure even product distribution across the screen surface. This technology performs gentle sifting without damaging the granule structure. Atlas Yem vibro sieves are particularly effective at recapturing dust generated after the cooling process (fines recycling), thereby preventing raw material waste.

The body structure is isolated to prevent vibration transmission to the floor, supported by heavy-duty springs and a robust chassis. With multi-deck options, you can simultaneously separate products of different sizes (e.g., fines, crumbles, pellets, and coarse particles) within a single unit. The quick-change screen frames and dust-tight sealing gaskets increase operational efficiency while minimizing maintenance downtime.

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Shaky Sieve All Products

The final and most critical stage of the feed production process is ensuring the product is free from dust and unwanted particles before packaging. Atlas Yem Shaky Sieve systems flawlessly classify pellets or crumbles based on size after the pelleting process. This technology enhances the quality of the final product while maintaining PDI (Pellet Durability Index) standards, thereby guaranteeing customer satisfaction.

High Vibration Efficiency and Durability

Also known in the industry as a vibrating screen or shaker sieve, this unit generates powerful vibrations via an eccentric drive system or vibro motors. This motion ensures the product spreads evenly across the screen surface, effectively separating fines through the mesh. Atlas Yem shaky sieves direct only the standard-sized, high-quality feed to packaging, while recirculating the separated fines back into the production loop to prevent raw material waste. Thanks to its steel construction and heavy-duty spring suspension system, it operates stably and quietly even under high-tonnage production loads.

Atlas Yem | Feed Milling, Flaking & Recycling Technology

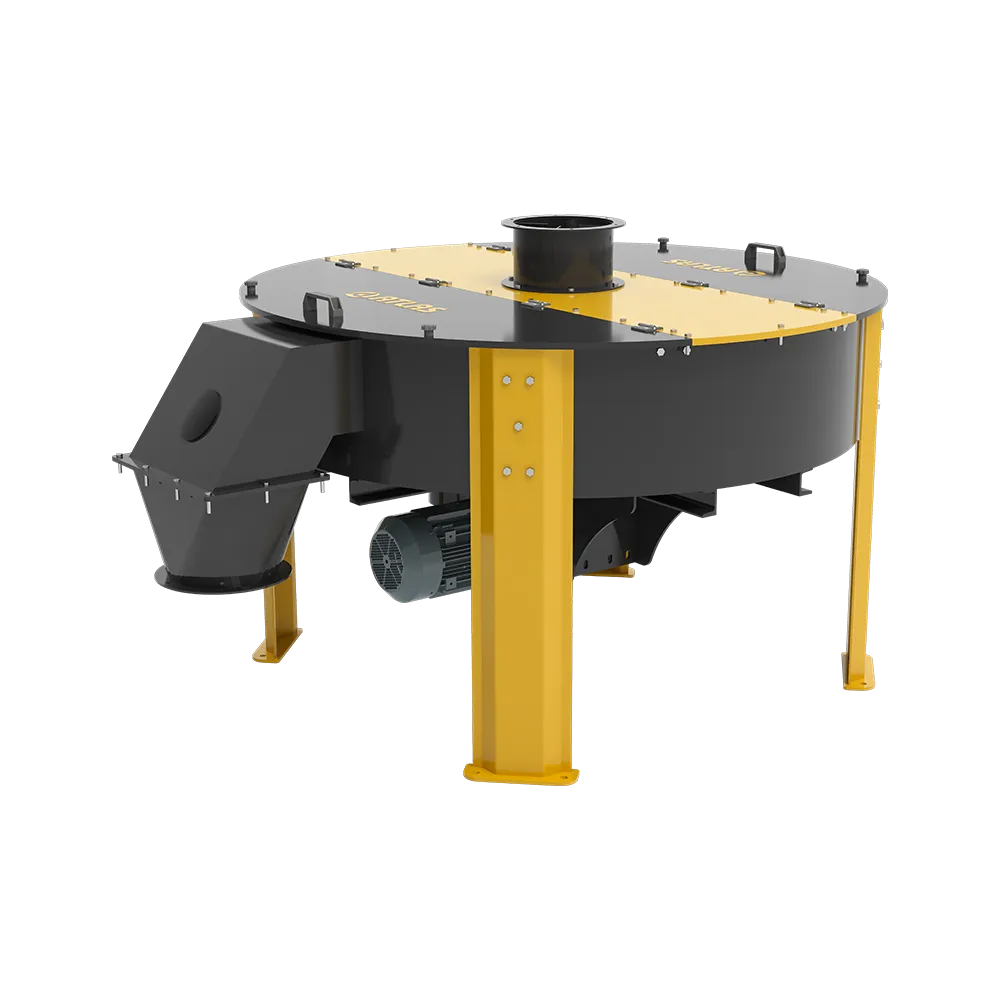

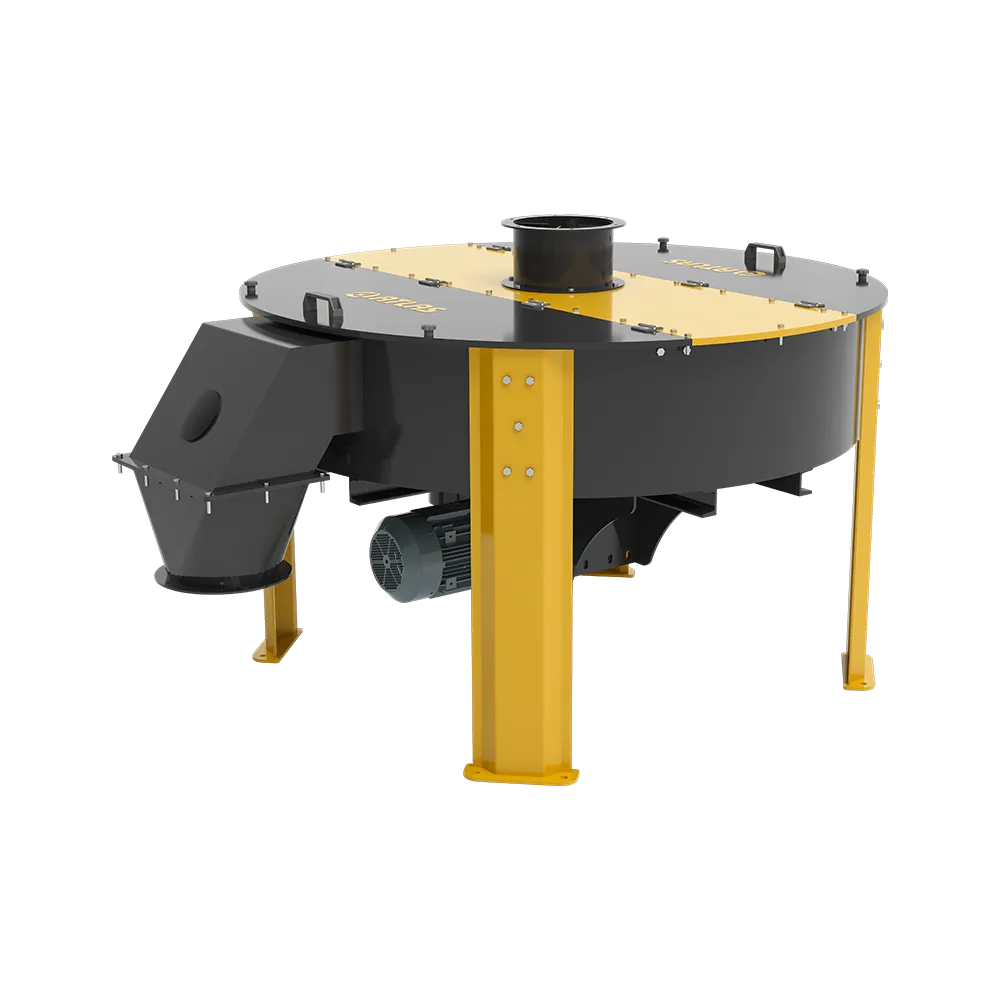

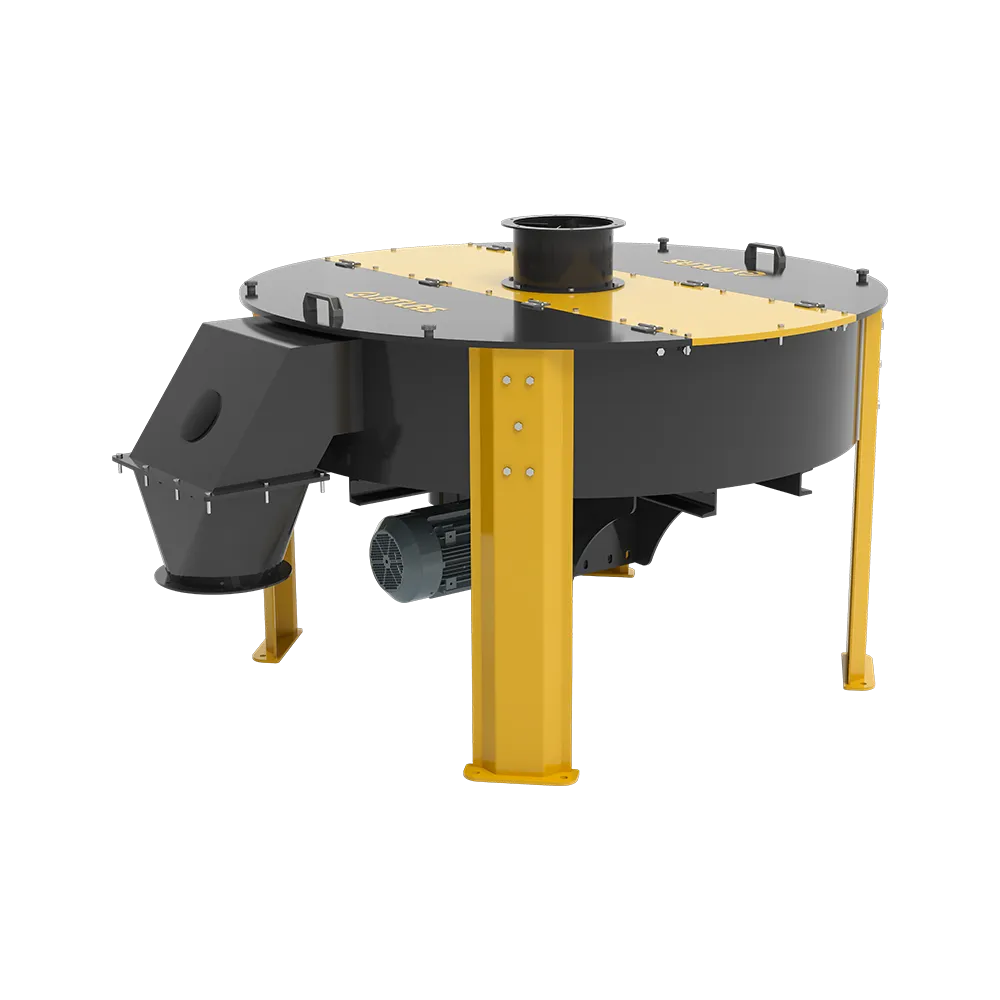

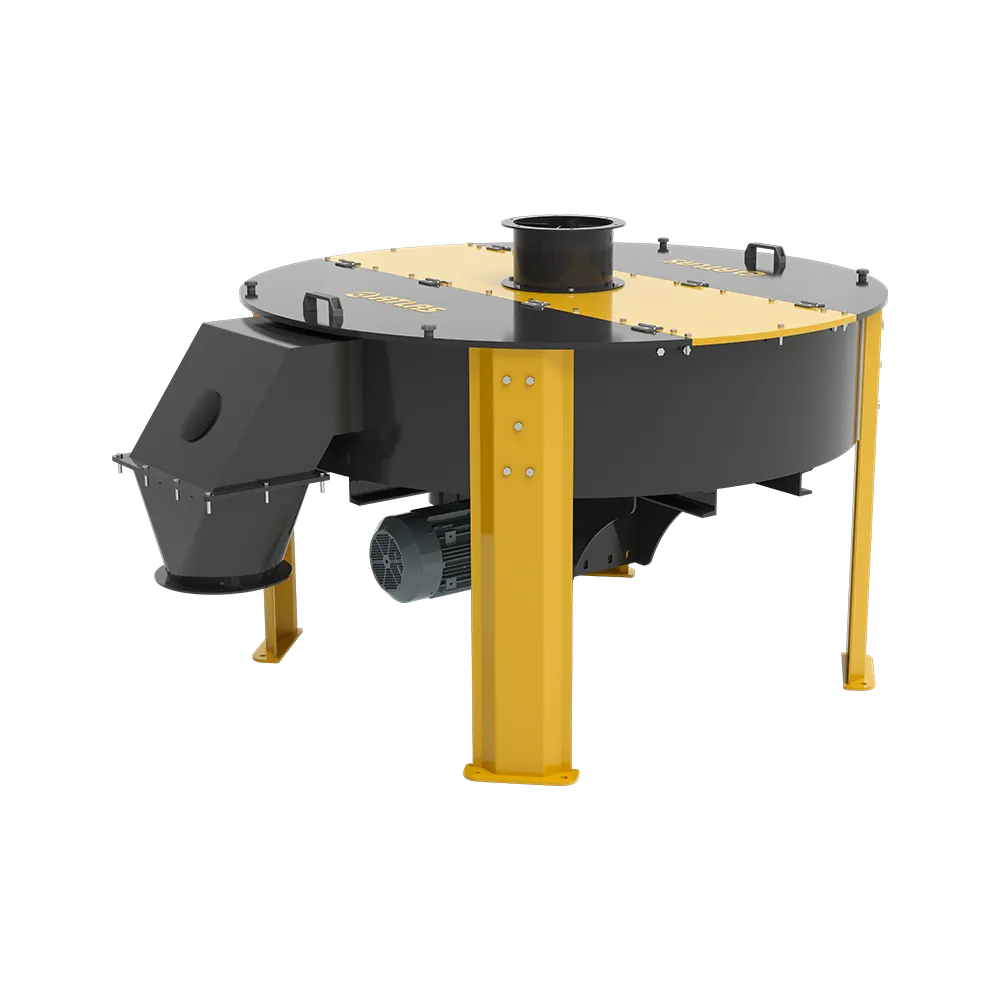

Circle Sieve All Products

One of the most critical stages in feed production is the accurate classification of pellets or granules. Atlas Yem circle sieve systems utilize a circular motion principle, ensuring that raw materials remain on the screening surface longer for unrivaled separation precision, even with the finest particles. Designed for dust-free and homogeneous final products, this technology elevates your facility's quality standards to a global level.

Advanced Circular Classification for Superior Pellet Quality

Often referred to in the industry as a rotary sifter or gyratory screener, the circle sieve provides a gentler screening process compared to traditional shakers. This ensures that pellets are graded without breakage, preserving critical PDI (Pellet Durability Index) values. Vibration is minimized through specialized balance weights, ensuring silent and long-lasting operation. Atlas Yem’s advanced engineering rapidly separates unwanted fines and recirculates them back into production, eliminating raw material waste.