ASS2503 Shaky Sieve | 20 T/H Capacity | Atlas Yem

ASS2503

ASS2503

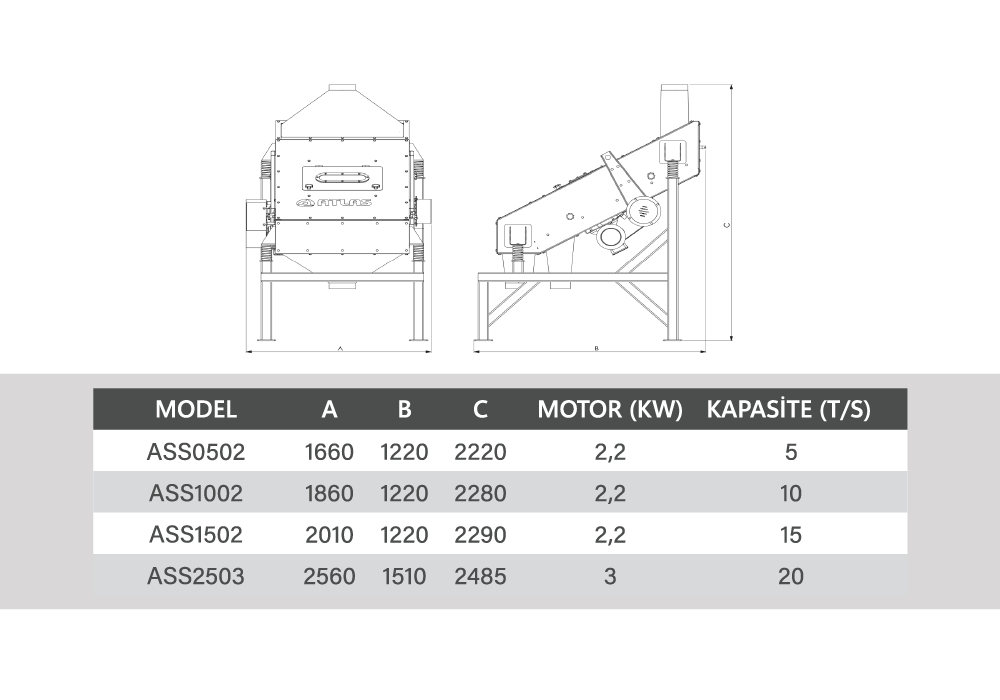

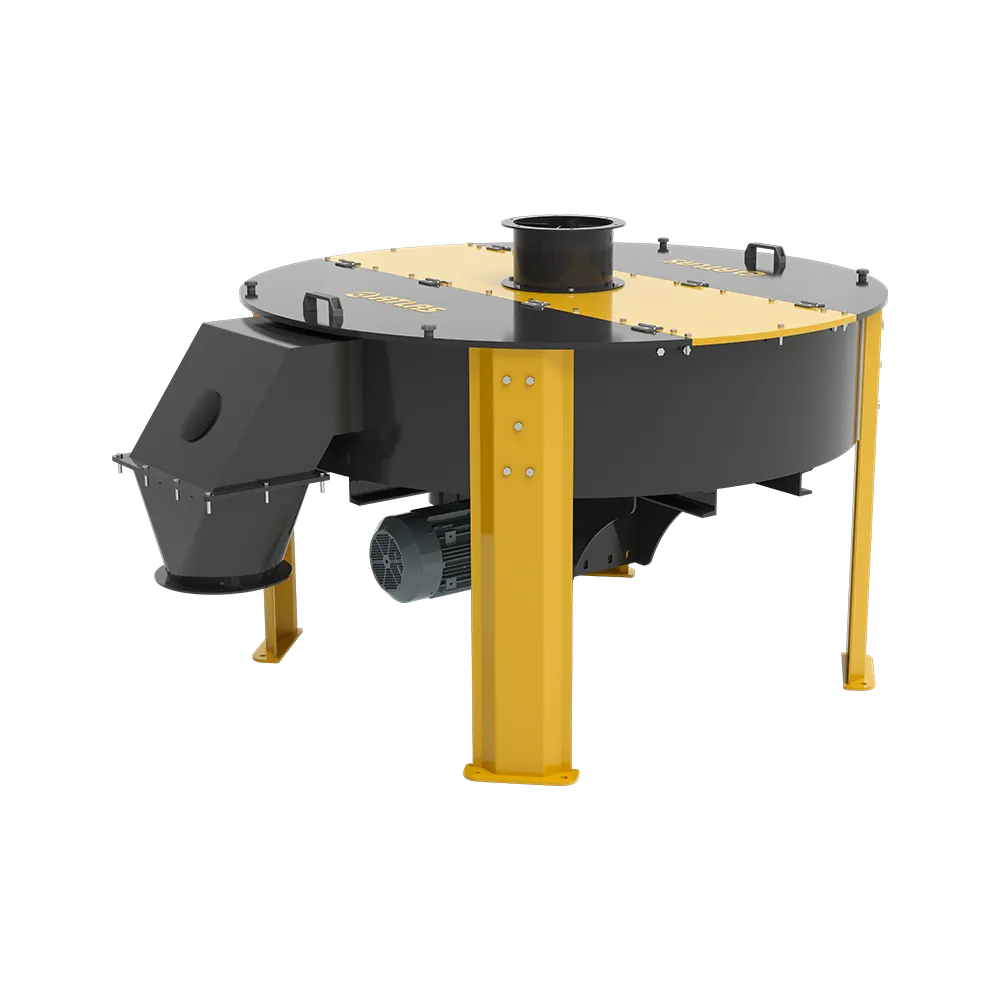

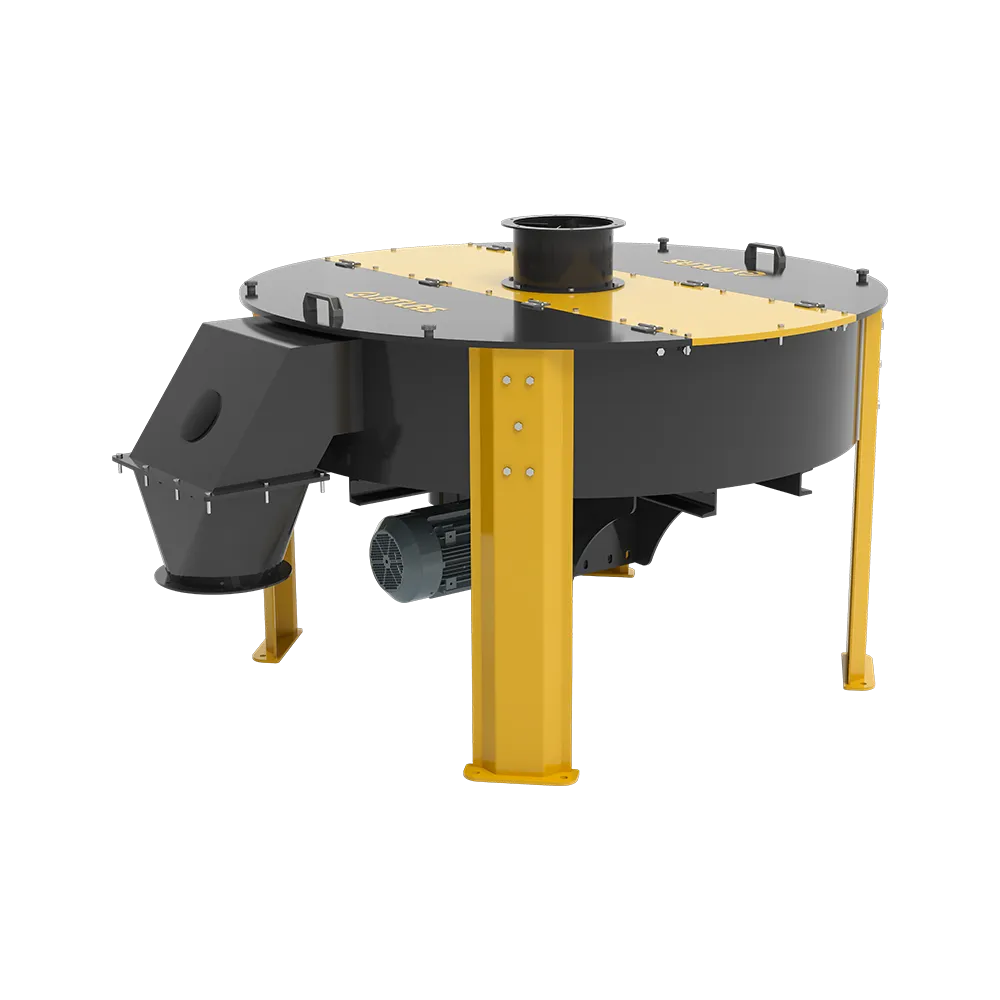

The ASS2503 represents one of the most dynamic screening solutions defining the quality standards of modern feed production lines. Boasting a substantial capacity of 20 tons per hour (20 T/H), this unit utilizes its high-torque 3 KW motor to ensure the seamless classification of granular products based on size. Engineered by Atlas Yem, this shaky sieve guarantees that the product is completely purified from foreign materials and unwanted dust particles (fines) before reaching the final packaging stage. Combining the speed required by high-capacity facilities with superior energy efficiency, the ASS2503 standardizes ration quality across every batch. As an indispensable component of dust-free feed manufacturing, this system both reduces operational costs and perfects the physical form of the feed reaching the end-user. Its powerful oscillating mechanism prevents clogging, maintaining a continuous flow and keeping the plant's output at peak levels.

In professional feed technology, granule classification directly impacts final market value. The Atlas Yem ASS2503 Shaky Sieve plays a critical role in processing various sizes of granular products with millimetric precision. Based on the sieve diameter and mesh structure, this cleaning process directs standardized feed to the main process while routing off-spec particles or fine dust back into the system for reprocessing.

This "zero-defect" approach prevents raw material waste and maximizes overall plant yield. Thanks to Atlas Yem’s reinforced compact structure, it absorbs vibration within the frame, offering quiet and stable operation. Also known in the industry as a vibrating grader or pellet screener, this model integrates easily into any animal nutrition or grain processing line. Its rational design is a masterpiece of engineering that shortens maintenance cycles while extending the operational lifespan in demanding industrial environments.