Industrial Mixing Systems & Feed Mixers | Atlas Yem

Mixing Systems

Mixing Systems - Products

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Mixing Systems All Products

Mixing Systems: The Art of Homogeneity in Feed Production

The most critical stage of a feed production line is the precise merging of all ration components. Atlas Yem mixing systems guarantee an equal distribution of every particle, from micro-ingredients to bulk raw materials. In modern livestock farming, efficiency depends on every single pellet or mash feed carrying the exact same nutritional value. Atlas Yem technology transforms this high standard into reality with a remarkably low Coefficient of Variation (CV).

Why Choose Atlas Yem Mixer Technologies?

Establishing the balance between speed and precision in industrial mixing processes requires superior engineering. Our product range, including horizontal mixers, twin-shaft paddle mixers, and ribbon mixers, is optimized for the specific needs of facilities with varying capacities. While aiming for maximum tonnage with short mixing cycles, our gentle paddle designs prevent damage to the raw material's structure, preserving product integrity. Furthermore, our liquid injection-ready housing ensures additives like oil and molasses are integrated without clumping.

Operational Power and Technical Superiority

Atlas Yem feed mixers are more than just mixing tanks; they are long-term investment assets. Pneumatically controlled full-length discharge gates (bomb-doors) prevent cross-contamination between batches and reduce discharge time to mere seconds.

16 from the product 13–16 Showing between

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Melassier All Products

Melassier: Precision Molasses Integration in Feed Technologies

In the production of high-energy animal feed, the uniform distribution of molasses is vital for both nutritional value and physical quality. The Atlas Yem Melassier is a high-speed continuous mixer specifically engineered to integrate molasses, oils, and other liquid additives into the feed mash without any clumping or balling issues.

Advanced Continuous Liquid Mixing and Coating

Atlas Yem melassier technology ensures that every particle of the raw material is coated with a fine layer of liquid. The specially designed paddle angles and high-velocity rotor system facilitate a perfect bond between the liquid and solid phases within seconds. This process not only enhances the feed's energy density but also improves pellet durability (PDI) and reduces energy consumption during the pelleting process by lowering die friction.

Atlas Yem | Feed Milling, Flaking & Recycling Technology

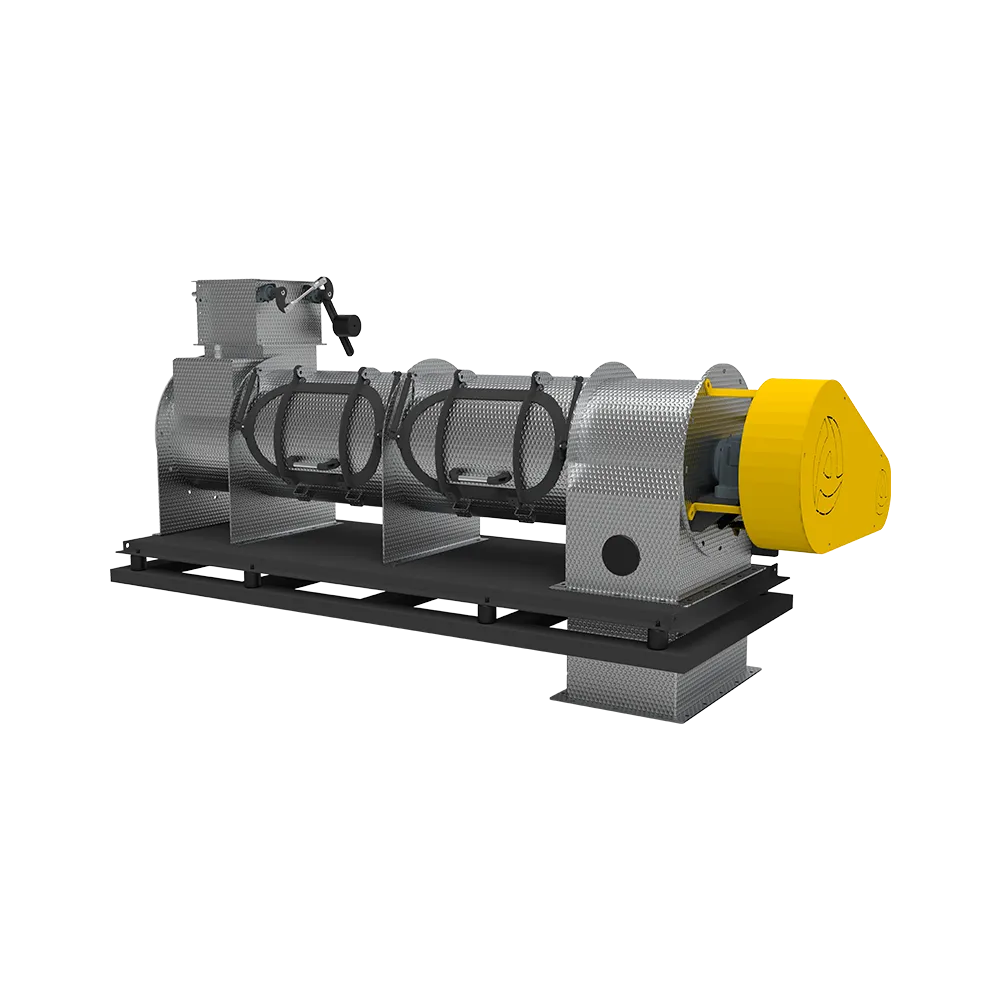

Single Shaft Mixer All Products

Single Shaft Mixer: Excellence in Industrial Mixing

The core of a successful feed production line is the mixer unit, where all micro and macro ingredients merge in perfect harmony. Atlas Yem single shaft mixer solutions provide high homogeneity standards that guarantee the same nutritional value in every particle of the ration. The precise balance required for modern livestock is achieved through our advanced engineered paddle designs.

Maximum Efficiency and Superior CV Values

Standing out in mixing systems for its durability and performance, this unit is optimized to achieve the highest mixing quality in the shortest possible time. Thanks to the specially angled paddle or ribbon flights, it ensures effective circulation without damaging the material structure. Atlas Yem technology standardizes your product quality with a world-class low Coefficient of Variation (CV). Its structure is fully compatible with liquid injection systems, allowing additives like oil and molasses to be integrated without clumping.

Atlas Yem | Feed Milling, Flaking & Recycling Technology

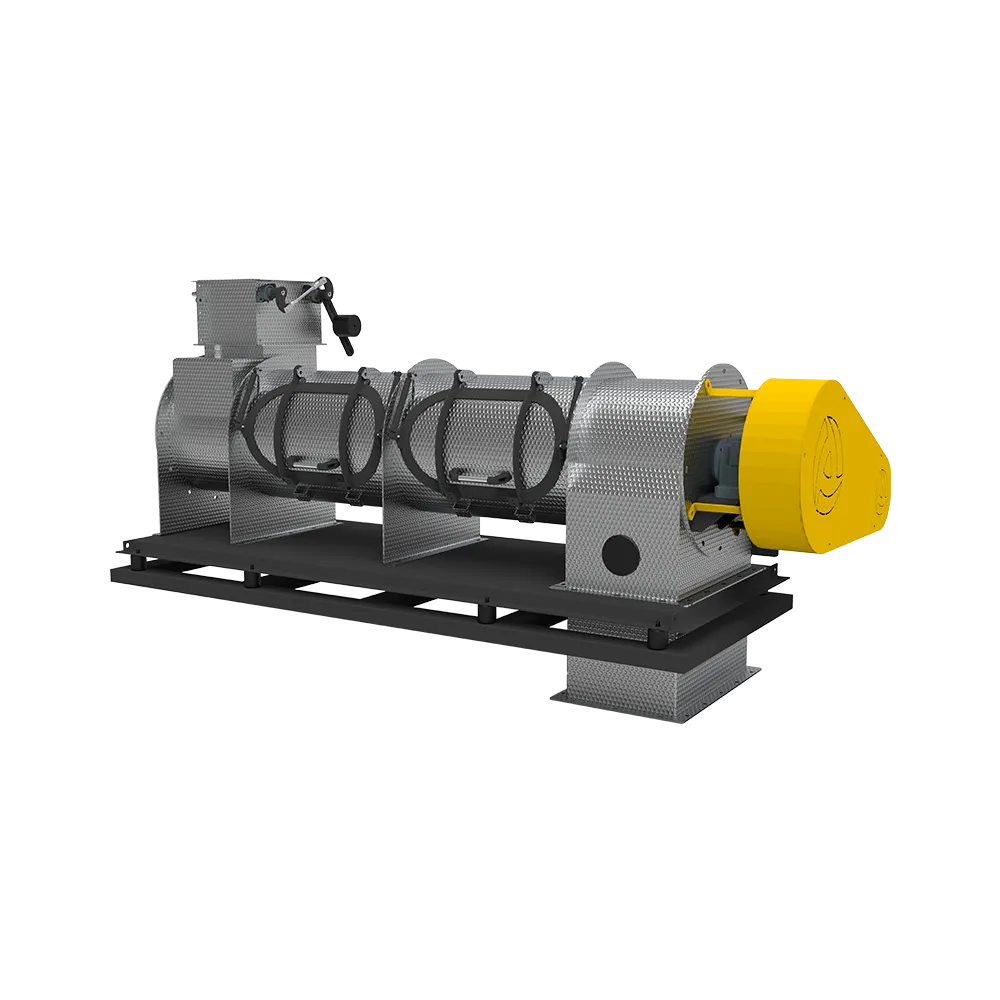

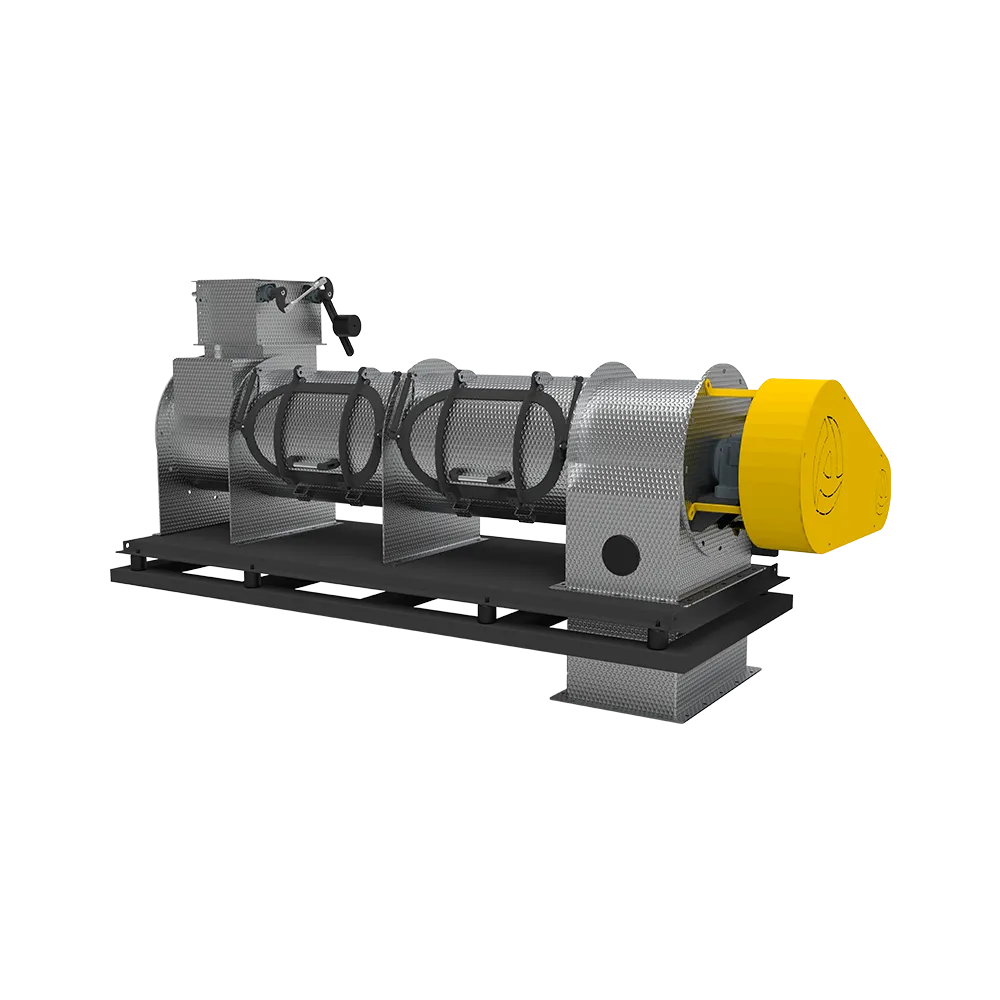

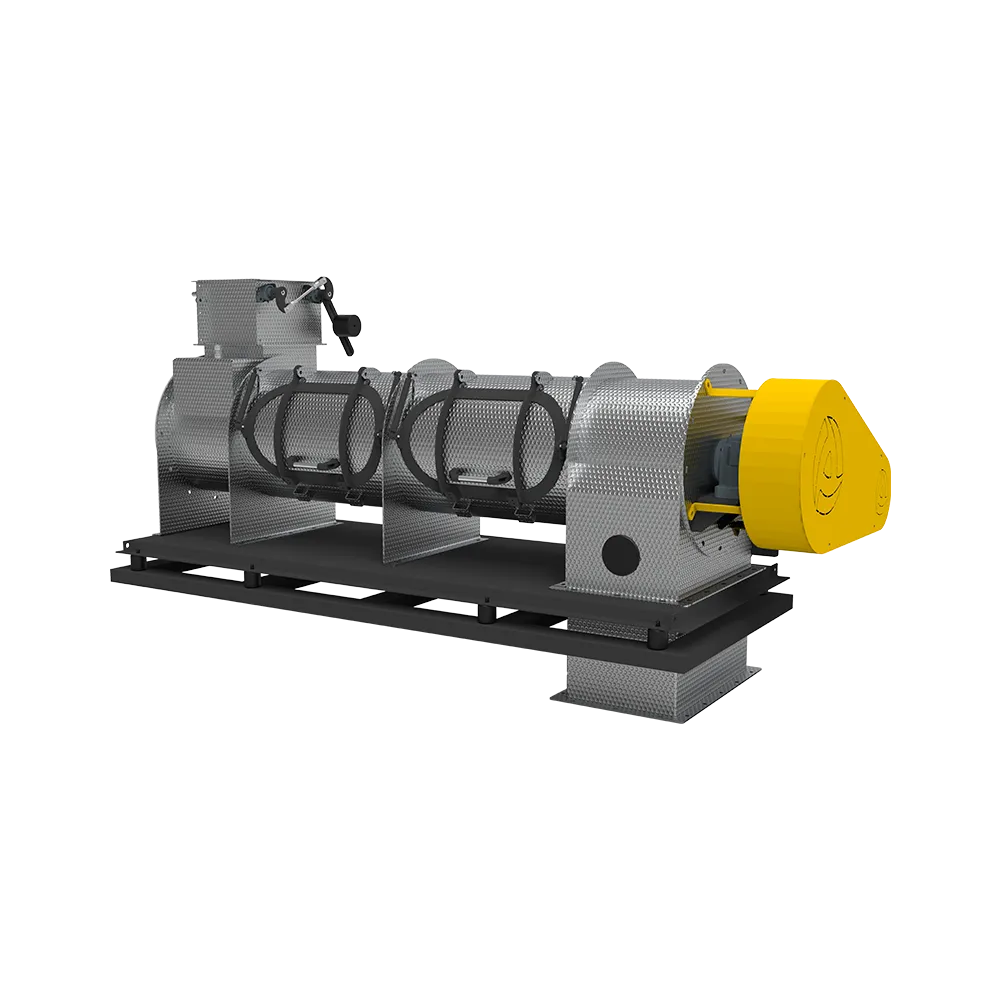

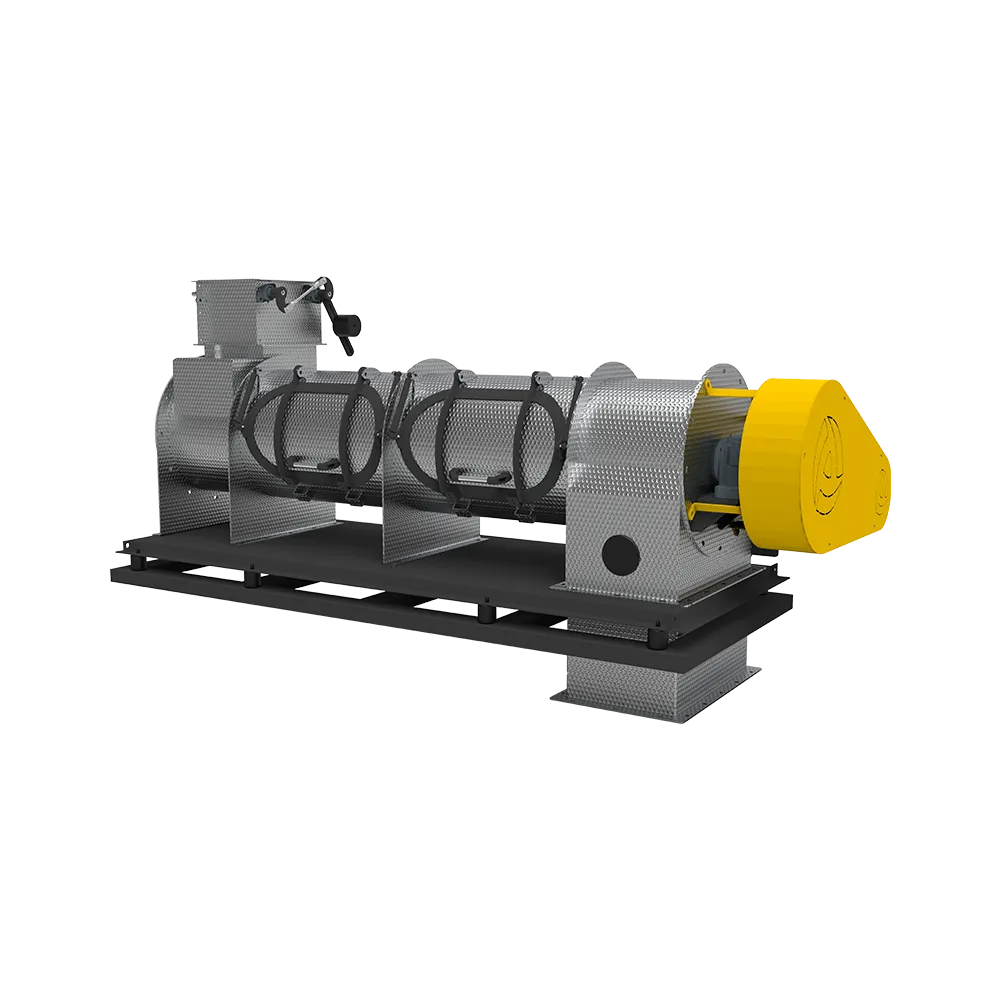

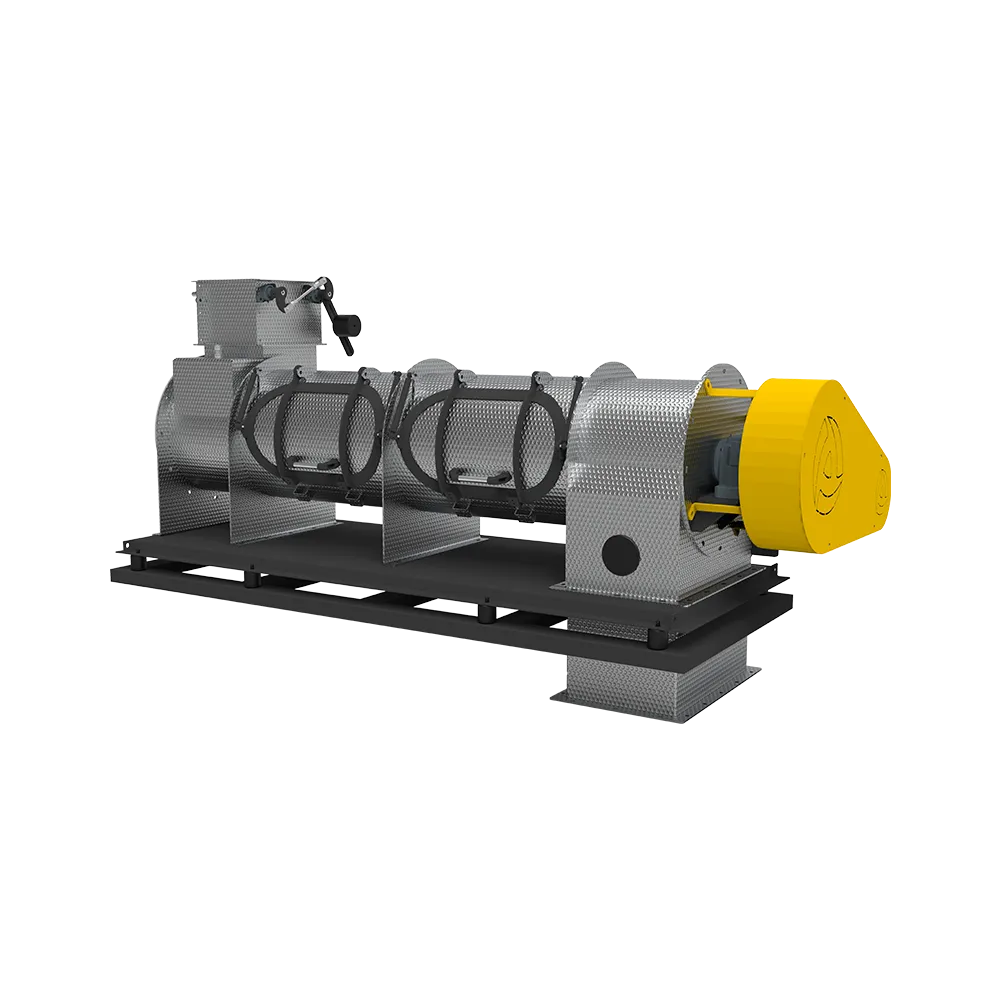

Double Shaft Mixer All Products

For feed production lines aiming for both extreme speed and flawless homogeneity, the double shaft mixer represents the ultimate technological solution. Engineered by Atlas Yem, this system ensures that micro-ingredients and liquid additives are distributed equally throughout the ration within seconds. The low Coefficient of Variation (CV), essential for modern livestock efficiency, becomes an industrial standard with this high-performance unit.

Fluidized Bed Principle and Rapid Cycle Times

The twin-shaft architecture utilizes counter-rotating paddles to create a "weightless zone" within the mixing chamber. Known as the fluidized bed principle, this technology completes even the most sensitive blends in record times of 30-60 seconds without damaging the physical structure of the raw materials. The paddle mixer design prevents clumping and ensures a smooth output, particularly in complex recipes requiring high levels of liquid injection such as oil or molasses.

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Oil Coating Unit All Products

The final touch for high-performance feed production is the precise application of liquids post-pelleting. The Atlas Yem Oil Coating Unit is meticulously engineered to apply fats, oils, enzymes, or other liquid additives uniformly onto the pellet surface. This technology not only optimizes the energy density of the feed but also significantly reduces dust and enhances the overall palatability and visual appeal of the final product.

Precision Atomization and Surface Excellence

Operating on advanced atomization principles, Atlas Yem coating systems break down liquids into micro-particles. This ensures that every pellet is coated evenly without excess moisture or untreated areas. By strengthening the physical structure of the feed, the unit boosts the PDI (Pellet Durability Index), preventing breakage and fines during transport and storage. Integrated with precision dosing pumps and continuous flow sensors, the system guarantees 100% formulation accuracy.

Operational Efficiency and Structural Integrity

Whether you are producing high-energy broiler feed or premium cattle rations, the Oil Coating Unit provides the scalability required for modern industrial lines. Its robust construction and easy-to-clean design ensure long-term reliability and strict hygiene standards.